|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

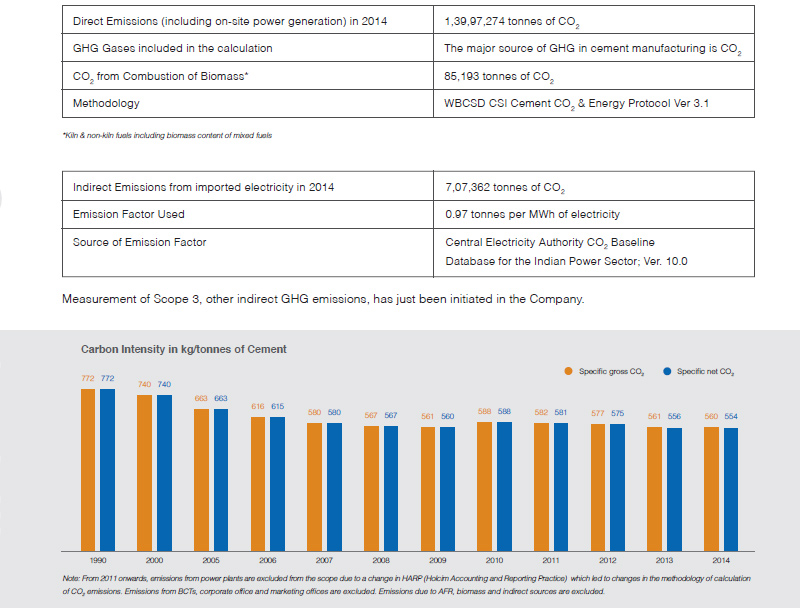

| Carbon and Other Emissions |

| We have continued to focus on climate change mitigation

and footprint-conscious growth as an integral part of our

sustainability strategy. We focus on low carbon growth,

use of alternative fuels, renewable energy, biomass etc.

We continue to progress on our renewable and clean

energy roadmap. As a part of that, we installed a 330 KV

solar power station at Bhatapara, Chhattisgarh in 2012, in

addition to the existing 7.5 MW wind energy plant at

Kutch, Gujarat, which was commissioned in 2011.

A 6.5 MW waste heat recovery based power generation

system is being installed, which is expected to be

operational by 2015.

Partnership for Climate Mitigation The Company is one of the Co-chairs of CSI India and has been part of the working group on ‘A Low Carbon |

Technology Roadmap for Indian Cement Industry’. The strategies mentioned in the roadmap are now being piloted at our Ambujanagar unit with the help of CII. The focus is on energy efficiency opportunities in the operations. Carbon Disclosure Project The Company is currently monitoring and reporting CO2 emissions as per the WBCSD Cement Sustainability Initiative (CSI) protocol. Ambuja proactively discloses its carbon emissions and strategies to address climate risks annually in the Carbon Disclosure Project (CDP). The Company scored 92 out of 100 on the CDP 2014 cycle. The Company has been rated among the top 10 in the Climate Disclosure Leadership Index 2014, issued by CDP for India. |

|

| In 2014, Ambuja utilised over five million tonnes of fly ash

which resulted in PPC constituting over 92% of its overall

cement production. The carbon footprint of our product

has reduced by over 28% from 1990 levels (for direct

emissions). We continue to participate in the Global

Programme of Clean Development Mechanism (CDM).

Currently we are pursuing our CDM project on waste heat

recovery based power generation in our integrated unit in

Rabriyawas, Rajasthan.

Our cement production process does not emit ozonedepleting substances (ODS). We have ascertained that the offices within our plants are also free from ODS emitting equipment like air conditioning systems, fire suppression equipment, refrigerators etc. |

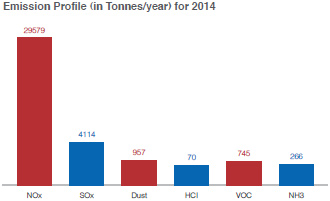

NOx, SOx, and other significant air emissions by type and

weight emissions from the nine kiln/raw mill stacks are

reported, excluding captive power plants and other stacks. NOx, SOx, and other significant air emissions by type and

weight emissions from the nine kiln/raw mill stacks are

reported, excluding captive power plants and other stacks. |

|

|