Ambuja Cements is enhancing its market position by making strategic investments in efficiency, cost competitiveness, and sustainability. With a well-balanced approach to greenfield and brownfield projects, land acquisition and approvals are in place. By implementing technologies such as zero-carbon heating, and waste heat recovery systems, the Company ensures enhanced energy efficiency and full adherence to ESG standards. Ambuja Cements’ growth strategy combines both organic and inorganic approaches, featuring several ongoing expansion projects that utilise cutting-edge technologies and strict quality controls to ensure sustainable development.

Focus Areas

| Capacity Expansion |

Enhancing Efficiency |

Sustainable Manufacturing |

Quality Improvement |

|---|---|---|---|

|

Development and Key Initiatives

|

|

|

|

|

Key Performance Indicators

Capacity expansion projects across country:

140 MTPA

Capacity by FY 2027-28 |

19%

cost reduction achieved since integration into Adani Group

376 MW

WHRS Capacity by FY '28

76 kWh/t Cement

Energy consumed per tonne of cementitious material

23% TSR

By 2030

65%

of total cost shares synergies with Group Companies |

78%

blended green cement products with GRIHA certification

60%

Of overall energy consumption from renewables and green by FY'28

1 GW

Of solar & wind energy by

299 MW

Solar and Wind Power operationalised

ISO 50001

Certified Operations |

100% compliant with BIS parameters 100% of our plants are ISO 9001 Certified Hourly quality monitoring conducted from quarry to lorry for superior grade cement to our customers R&D fueled manufacturing to create wide range of customised premium and sustainable products Developing Future-Ready platforms XRAY Diffraction(XRD) spectrophotometer and Application-based products |

Material Topics

- 1 Capacity Utilisation and Current Demand

- 2 Land Acquisition for Mines and New Operations

- 3 Energy Efficiency

- 4 Compliance to Regulatory Requirement

Stakeholders Impacted

-

Suppliers

Suppliers

-

Employees

Employees

-

Government and Regulatory Bodies

Government and Regulatory Bodies

-

Construction Professionals

Construction Professionals

SDGs Impacted

Overview

Ambuja Cements' manufactured capital encompasses the physical assets that support its operations, including land, buildings, production plants, leased mines, machinery and equipment.

Clinker Production

Cement Production

Manufacturing Highlights of FY 2024-25

Thermal Power Generated (Mn Units)

Thermal Substitution Rate (TSR) achieved

WHRS Power Generated (Mn Units)

Waste Co-processed

Green Power Consumed (Mn Units)

Clinker Factor

Specific Thermal Energy Consumption

Specific Electrical Energy Consumption

Ambuja Cements’ Value Chain

Being one of the largest cement companies in India, Ambuja Cements goes above and beyond to ensure seamless processes across its value chain to provide high quality cement.

|

|

|

|

|

|---|

| Raw Material Sourcing | Raw Material Preparation | Clinker Production | Cement Grinding and Blending |

|---|---|---|---|

|

Ambuja Cements extracts essential raw materials like limestone, clay and laterite from quarries. The Company’s advanced mining techniques ensure the sustainable extraction of these resources while minimising environmental impact.  |

Once extracted, the raw materials are crushed and grounded into fine powder to ensure homogeneity. These materials are then blended in precise proportions using automated systems to achieve the desired chemical composition, forming the foundation for quality cement Ambuja Cements produces.  |

The blended raw materials are fed into rotary kilns, where they are subjected to extremely high temperatures (1400– 1500°C) to form clinker, the key intermediate product in cement manufacturing. To ensure sustainability, Ambuja Cements invests in alternative fuels and energy-efficient kilns to reduce greenhouse gas emissions and energy consumption.  |

The clinker is cooled and mixed with gypsum and other additives before being finely ground in advanced grinding mills. This stage allows for the production of different types of cement, catering to diverse consumer needs.  |

|

|

|

|

|---|

| Packaging and Storage | Logistics | Sales and Technical Assistance |

|---|---|---|

|

Once the cement is produced, it is packaged into bags or loaded in bulk, depending on customer requirements. Ambuja Cements has deployed proper storage facilities to ensure the product retains its quality by preventing exposure to moisture and other contaminants.  |

Ambuja Cements ensures that cement reaches distributors and construction sites promptly through its world-class logistics. The cement is transported via road, rail or sea, depending on proximity and volume, with Ambuja Cements leveraging advanced tracking systems to optimise delivery routes and minimise costs.  |

The Company thrives in the business landscape through extensive market research and branding to differentiate their offerings. Ambuja Cements has built strong relations with its distributors, contractors and end-users, ensuring a robust market presence. The Company also provides technical assistance to customers.  |

Development

The Company is committed to being the lowest-cost cement manufacturer in the world while delivering the highest quality and has continued to make substantial investments to strengthen its market presence, with a focus on improving efficiency, enhancing cost competitiveness, and promoting environmental sustainability to secure a competitive edge.

Capacity Expansion

Ambuja Cements follows a balanced growth strategy, capitalising on both greenfield and brownfield projects. Its expansion plan combines a strategic mix of organic and inorganic initiatives, ensuring both sustainable and accelerated growth. The Company currently has 12 ongoing expansion initiatives, which are expected to add 19 MTPA of cement capacity and 11 MTPA of clinker capacity, with phased commissioning beginning in Q4 FY 2024-25. Additionally, the Board has approved new cement grinding units at various locations, which will increase cement capacity by another 21 MTPA and clinker capacity by 16 MTPA. All these projects are progressing with land acquisition and statutory approvals in place. The new assets will be powered by Waste Heat Recovery Systems (WHRS) and Alternative Fuels and Raw Materials (AFR), ensuring optimal energy efficiency and full compliance with ESG standards.

| Expansion Project | Capacity (MTPA) | |

|---|---|---|

| Clinker | Cement | |

| Bhatapara Line 3 (CU) | 4.0 | - |

| Sankrail (GU) | - | 2.4 |

| Sindri (GU) | - | 1.6 |

| Salai Banwa (GU) | - | 2.4 |

| Bathinda | - | 1.2 |

| Marwar (GU) | - | 2.4 |

| Maratha Line 2 (CU) | 4.0 | - |

| Dahej Line-2 (GU) | - | 1.2 |

| Kalamboli (Blending) | - | 1.0 |

| Jodhpur (Penna IU) | 3.0 | 2.0 |

| Krishnapatnam Penna (GU) | - | 2.0 |

| Warisaliganj (GU) | - | 2.4 |

| Total | 11 | 19 |

Raw Material and Fuel Security

To ensure self-sufficiency, Ambuja Cements is acquiring coal and limestone mines which will enable the Company to meet a substantial amount of its requirements. Ambuja Cements is strategically positioned for long-term success, backed by vast limestone reserves that support its growth ambitions. With secured land and abundant mineral resources, the Company is primed for continued expansion. With 40% of our Fly-Ash requirement under long-term arrangements, we have strong long-term material security to support our cost leadership journey.

Captive Raw Material Reserves

Ambuja Cements has significantly bolstered its limestone reserves to around 9,000 million tonnes, ensuring a stable supply of essential raw materials for sustainable production.

Energy

Ambuja Cements is in the process of implementing several green energy contracts which are aligned with and support the Group’s broader sustainability objectives.

Ambuja Accelerates Renewable Energy Initiatives

Ambuja Cements has commissioned 200 MW solar power project in Khavda, as well as 99 MW wind power project, as a key part of its ambitious 1 GW renewable energy strategy. Out of the remaining 707 MW of solar and wind power, 70% projects are slated for completion by June 2025, and the balance by December 2026. This initiative unlocks savings in power cost of 70% while bringing the Company closer to its bold goal of achieving Net Zero emissions by 2050, underscoring its commitment to sustainability and environmental leadership.

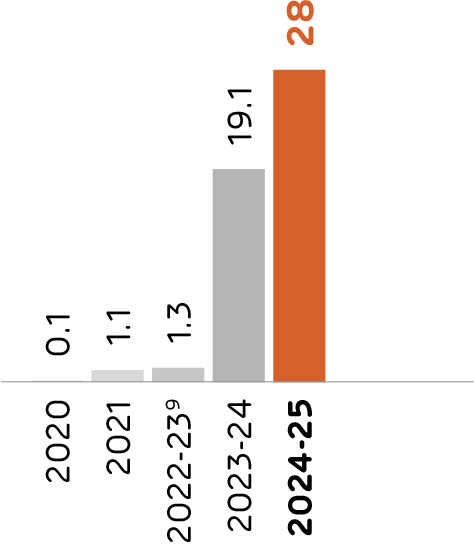

Renewable and Green energy % of total energy mix

(in %)

Logistics

Ambuja Cements is committed to significantly reducing its logistics costs through digitalisation and optimising lead distances by approximately 100 km, achieved by restructuring plant and warehouse footprints. This is further supported by the Company’s M&A activities, which have expanded its network of Bulk Cement Terminals to 11, along with a strengthened presence along the coastline of Peninsular India.

Additionally, Ambuja Cements is deploying 60 specialised Bogey Covered Fly-Ash/Cement (BCFC) rakes for the long-term sourcing of fly-ash, facilitated through synergies within the Adani Group. The Company is also pioneering marine logistics in the cement industry, capitalising on its extensive and growing coastal footprint. By leveraging strategic coastal locations, Ambuja Cements is driving sustainable growth, reducing emissions, and handling larger volumes, ultimately lowering overall logistics costs.

We are also deploying specialised EV trucks, and the introduction of BCFC rakes enable us to handle large volumes with ease while reducing costs further.

The new electronic Proof of Delivery (ePOD) system is revolutionising the logistics industry by boosting efficiency and transparency.

It eliminates paper-based processes, reducing administrative tasks and minimising errors. The multi-channel confirmation process offers channel partners great flexibility, simplifying delivery confirmations across various platforms. The ePOD vendor billing portal strengthens vendor relationships with transparent and swift payment processes. Real-time tracking ensures complete visibility for both channel partners and vendors, providing a seamless, touchless experience and simplifying freight bill submission through the portal.

Moreover, the addition of 11 General Purpose Wagon Investment Scheme (GPWIS) rakes for clinker movement and 60 Bogey Covered Fly-Ash/ Cement (BCFC) rakes for fly-ash transportation has enhanced supply chain reliability and cost-effectiveness.

9 Note: The Company had changed its financial year ending from December 31 to March 31. FY 2022-23 was for 15 months (January 01, 2022 - March 31, 2023). Therefore, the data for FY 2023-24 and FY 2024-25 is not comparable with the figures for the 15 months year ended March 31, 2023.

Initiatives driving Ambuja Cements’ Logistics Journey

| Go Direct | Ambuja Cements has continued its implementation of digital solutions to optimise the supply chain simultaneously, expanding the fleet capacity for D2C delivery. |

| Agile and Automated Logistics Infrastructure | Ambuja Cements continued the implementation of in-plant automation with advanced vehicle tracking, reducing truck turnaround times and significantly increasing dispatch capacity. ACL is continuously working towards a significant 100 km reduction in lead distances by optimising plant and warehouse footprints. The Company has added 11 GPWIS rakes to stabilise clinker supply and 60 BCFC rakes to be added for safe, cost-effective transportation of fly ash from power plants to cement plants. |

| Commercial Excellence | Advanced scientific models continue to optimise operations and strategically renegotiate freight and handling rates, enhancing cost efficiency and profitability. By integrating an electronic proof of delivery system with real-time tracking and a touchless freight billing process, it enhances logistical transparency, simplifies delivery confirmations, and ensures seamless vendor payments. |

| Push Towards Low-Cost Green Energy | The Company has continued its transition from diesel to CNG, LNG and electric fuels, reducing the Company’s carbon footprint while improving logistics sustainability and cost efficiency. |

| Real-time Demand and Supply Optimisation | Further integrated state-of-the-art digital tools for real-time order processing, ensuring optimal source matching based on cost-effectiveness and service quality. The Cement Network Operating Centre further optimises demand and supply, boosting operational efficiency and excellence. |

| Digital Transformation | Centralised logistics control tower for real-time performance monitoring, enabling proactive interventions to drive continuous operational excellence. Ambuja Cements also implemented advanced fleet management systems with AI-enabled tracking, ensuring 98% GPS coverage for real-time shipment tracking with accurate arrival times. The Company also captured unloading site identification through AI and highlighting route deviations, including monitoring of detention at the unloading site. |

| Coastal Logistic Infrastructure | Ambuja Cements has a fleet size of 14 dedicated sea vessels which enables the Company to dispatch 3 million tonnes of cement annually, significantly reducing carbon emissions, while operating across 11 strategically located terminals. Strong M&A activity has expanded the Company’s Bulk Cement Terminals (BCTs) to 11, boosting its coastal presence. The Company plans to add 10 more sea vesssels to transport cement and clinker to all 11 terminals efficiently and sustainably. |

of cement dispatched in FY 2024-25

LEADING IN LOGISTICS

- Enhanced presence across Indian coastline with 11 Bulk Cement Terminals

- 60 Specialised BCFC Rakes to be deployed

- 11 Owned GPWIS Rakes Efficient Movement which is Highest in the Industry

- 26 BCFC rakes had been ordered and 6 BCFC rakes have been inducted

- Modal shift in logistics: 10% Sea Transport by FY’28

- 100 km lead reduction targeted

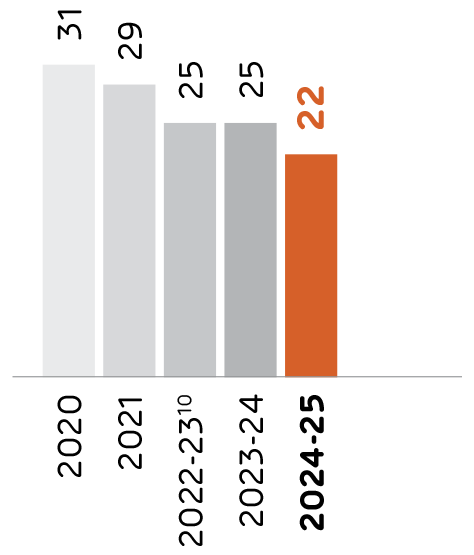

Freight and Forwarding Cost

(in %)

10Note: The Company had changed its financial year ending from December 31 to March 31. FY 2022-23 was for 15 months (January 01, 2022 - March 31, 2023). Therefore, the data for FY 2023-24 and FY 2024-25 is not comparable with the figures for the 15 months year ended March 31, 2023.

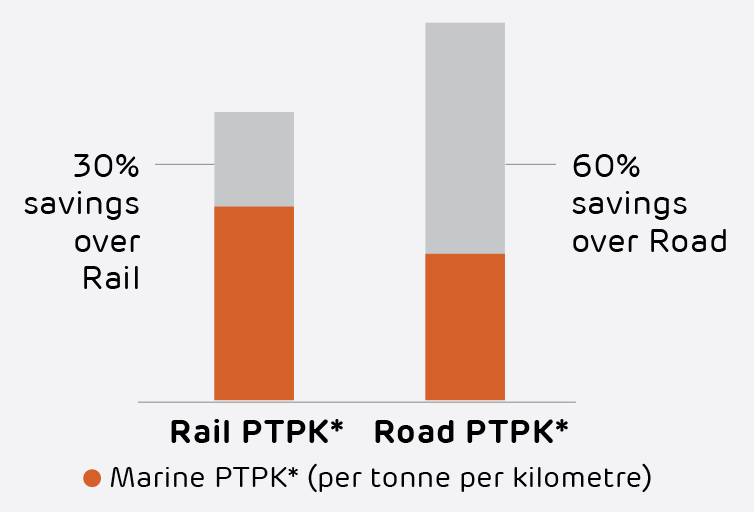

Driving the Future of Marine Logistics

Marine logistics is a cornerstone of operational excellence for Ambuja Cements. By expanding its strategic coastal presence, the Company improves efficiency, extends its reach, and elevates customer engagement.

As a leader in bulk cement transportation via coastal shipping in India, Ambuja Cements handles large volumes with unmatched cost efficiency. Through digitalisation, optimised lead distances, and the adoption of alternative fuels, the Company is focused on reducing emissions and advancing a sustainable future. Our strategically located Bulk Cement Terminals enable rapid, cost-effective distribution across peninsular India while significantly reducing emissions. With the Adani Group’s expertise in port infrastructure, Ambuja Cements ensures the smooth and sustainable transportation of cement and clinker.

Largest marine logistics operator in India

11 Captive Ships

11 Bulk Cement Terminals

1st in the industry

to use Green Fuel on captive ships

% Cost Savings in Marine Logistics

Driver Management Centres

Ambuja Cements has set up world-class Driver Management Centres (DMCs) at each of its plants, staffed with dedicated safety professionals to ensure the well-being of all drivers associated with the Company. These centres offer comprehensive defensive driver training, GPS tracking, and behaviour-based safety coaching, while also promoting road safety awareness through ongoing campaigns and active stakeholder engagement.

In addition to safety, the DMCs place a strong focus on drivers' health and welfare, offering regular health check-ups, eye screenings, nutritious meals, clean rest areas, and hygienic sanitation facilities.

Recognising drivers as integral to the business and key contributors to national progress, Ambuja Cements treats both drivers and their families with the highest level of respect and care. By enhancing road safety and improving the quality of life for drivers, the DMCs foster a ripple effect of positive change, securing futures, protecting society, and reflecting the Company's ongoing commitment to progress and social responsibility.

*PTPK - per tonne per km

Enhancing Efficiency and Safety through In-Plant Automation

Ambuja Cements' Digital In-Plant Automation initiative is a groundbreaking project designed to optimise logistics and elevate safety standards. Our advanced logistics systems leverage GPS, RFID and algorithms to ensure real-time tracking and seamless coordination. By equipping trucks with GPS tracking and introducing a comprehensive Safety Dashboard, the initiative aims to improve fleet management and operational oversight. This programme has since been extended to other plants, resulting in considerable operational advancements. Real-time GPS tracking ensures trucks follow designated routes and comply with safety regulations, while the Safety Dashboard provides detailed insights into fleet performance, incident reporting, and operational visibility.

This initiative underscores the Group’s 'Growth with Goodness' philosophy, which balances enhanced operational efficiency with the well-being of all stakeholders. In its first year, the programme successfully reduced route deviations, corrected freight distances, and achieved On-Time-In-Full (OTIF) dispatches, significantly improving logistics performance reducing logistics costs by ` 7 crores in the year.

Overcoming Implementation Challenges

Implementing GPS and Radio Frequency Identification (RFID technology across a wide range of fleet owners and transporter unions required strategic planning and collaborative engagement. Overcoming initial resistance was the key, and the Company focused on highlighting the mutual advantages of improved fleet management. A crucial step in gaining stakeholder buy-in was offering GPS devices at little or no cost, which alleviated concerns about financial burdens. Fleet owners quickly realised the system's value, particularly in pinpointing inefficiencies and optimising operational processes.

Key Benefits

The initiative has created an integrated network connecting sales, logistics, plants, channel partners, fleet owners, and customers, fostering seamless communication and collaboration. The Safety Dashboard now provides real-time monitoring, resource optimisation, and incident tracking. Leveraging AI to enhance data accuracy, even in remote locations, the system significantly reduces errors and ensures timely updates.

The implementation of GPS tracking has not only bolstered safety and operational efficiency but also helped in preventing theft and ensuring regulatory compliance. Fleet owners have reported substantial recoveries due to the system's real-time tracking capabilities, further increasing their trust and adoption. Customer satisfaction has improved as well, with accurate tracking enabling clearer communication and more reliable delivery timelines.

trucks running at a time with GPS monitoring, the highest in any industry

reduction in logistics route deviation through AI.

Plants of the Future

The Company has embraced world-class manufacturing standards by incorporating advanced technologies, optimising production processes and maintaining stringent quality control measures. It continues to focus on enhancing operational efficiency, reducing costs and minimising its environmental impact.

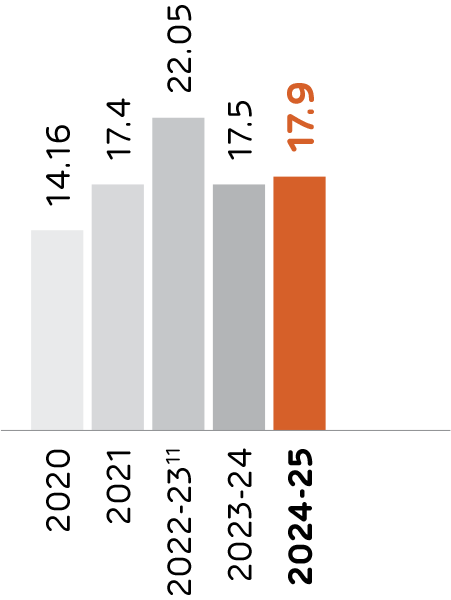

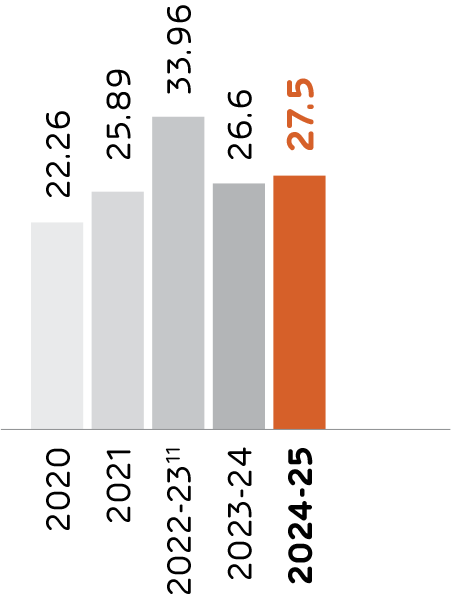

Clinker Production

Volume

(MMT)

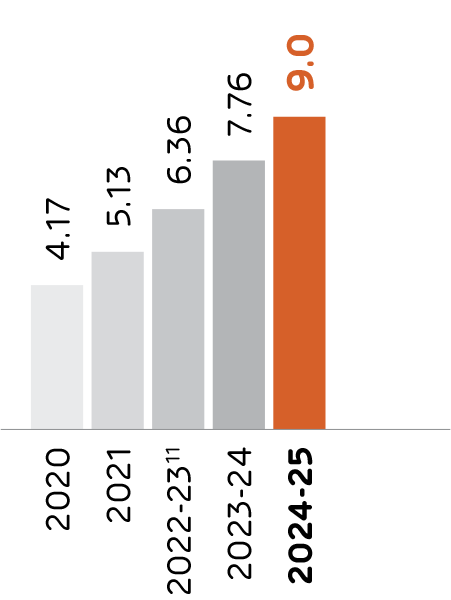

Cement Production

Volume

(MMT)

Thermal

Substitution Rate

(%)

Key Projects in FY 2024-25

GCV/NCV Integration with TIS: Integrated Gross and Net Calorific Value measurements with Laboratory Information Management System (LIMS) for accurate, real-time fuel quality tracking.

CTM Integration with TIS: Streamlined Coal Testing Methods through LIMS, automating data collection and improving testing efficiency and reliability.

Heat Accounting Application for Coal: Developed a Heat Accounting app to track coal’s heat value, enhancing fuel efficiency and identifying improvement areas.

IoT Vibration Analytics: Monitor equipment in real-time, predicting failures and reducing downtime.

App-Based WBI Reporting: Enabling real-time tracking of maintenance activities and improving team coordination and efficiency.

Cement Bag Tracking: Monitor movement from production to delivery, improving inventory management and reducing losses.

In-Plant Logistics: Optimise material movement, reducing delays and ensuring timely delivery across departments.

CCTV-AI for Print Anomaly Detection: Identify defects and ensure only high-quality bags are dispatched.

CCTV-AI for Bag Counting: Providing real-time data and reducing manual counting errors to enhance inventory accuracy and efficiency.

Chat GPT-Based Solution Operator: Assist production teams with real-time support, optimising processes and reducing downtime.

HLC (High-Level Control) for Kiln Mills: Improving performance, energy efficiency and product quality while reducing operational costs.

11Note: The Company had changed its financial year ending from December 31 to March 31. FY 2022-23 was for 15 months (January 01, 2022 - March 31, 2023). Therefore, the data for FY 2023-24 and FY 2024-25 is not comparable with the figures for the 15 months year ended March 31, 2023.

Enhancing Efficiency

Ambuja Cements is dedicated to investing in key areas of its operations, with the goal of becoming one of the most cost-competitive cement manufacturers in the country. Its strategic initiatives focus on reducing the clinker factor, improving energy efficiency, optimising raw material and fuel blends, enhancing power sources, and increasing the use of alternative fuels and raw materials in its production processes.

Increasing Line 1 Kiln Productivity from 3,120 to 3,800 TPD at Bhatapara unit

Challenges

The Bhatapara Kiln 1 had been facing frequent stoppages and significant efficiency losses, limiting production to just 3000 TPD. Issues such as recurring kiln brick lining failures, raw mill breakdowns, cooler misalignments, false air ingress, and damaged refractory were identified as key bottlenecks.

Impact

These problems led to major clinker volume losses, reduced energy efficiency, and frequent downtime, all of which hindered the kiln's ability to reach its desired capacity.

Benefits

To address these challenges, a cross-functional team implemented a series of targeted solutions during the kiln shutdown in June-July 2024. Key actions included replacing refractory in critical areas, cleaning the tertiary air duct, realigning the cooler, and upgrading the raw mill. These improvements successfully increased kiln productivity from 3120 TPD to over 3800 TPD, enhancing both operational efficiency and energy performance while reducing heat losses and downtime. The result was a significant boost in production capacity and long-term process stability.

Increase in Kiln Productivity

At Bhatapara plant

Technical Centre of Excellence

Ambuja Cements is committed (CoE) to advance Chairman Gautam Adani’s commitment to achieving Zero Carbon emissions in the Cement Business. The CoE is dedicated to enhancing reliability, productivity, and efficiency across manufacturing processes. By integrating best-in-class processes and systems, the CoE will play a pivotal role in new product development and the technical evaluation of upcoming projects and potential acquisitions, ensuring alignment with the overall business strategy.

Product Quality Management

Ambuja Cements is committed to delivering exceptional product quality, supported by a robust quality management system that ensures continuous monitoring and maintenance. Hourly quality monitoring conducted from quarry to lorry for superior grade cement to our customers.Focused on sustainability, Ambuja Cements maximises the use of low-grade limestone, replaces costly natural gypsum with affordable by-products, and optimises industrial waste for thermal substitution. The Company also enhances cement quality through innovative processing techniques to create wide range of customised premium and sustainable products and prioritises market-driven product development while striving to reduce its carbon footprint.

Ambuja Cements continues to lead the industry with future-focused initiatives and advanced energy management, driving sustainability. By prioritising cost optimisation and responsible growth, the Company is dedicated to delivering the highest quality cement at the most competitive prices, creating long-term value for its stakeholders.

compliant with BIS parameters

Drone Monitoring for Safe Operations

The Company is continuously advancing its manufacturing capabilities by integrating the latest technologies for more efficient operations. Drones are deployed across various plant functions, including ultrasonic thickness measurements for chimneys and ducts, inspections of welding and bolting in areas like preheaters, conveyor structures and clinker silo domes. Thermal imaging is used to monitor cyclones and other high-temperature areas, while volumetric measurements are taken for both covered and uncovered stockpiles.

Drones also enhance safety by inspecting PPE usage, monitoring critical activities during shutdowns, and ensuring proper housekeeping. They assist in mapping and contouring mines, improve security, and conduct confined space inspections in cyclones, silos, kilns and chimneys. Additionally, drones facilitate internal and external area surveys, monitor trucks and inspect hard-to-reach areas.

Cost Efficiency

Ambuja Cements has launched several initiatives to optimise costs across its operations. The Company is relentlessly focused on cost optimisation and is committed to deliver the highest quality cement at the lowest cost. Fuel cost savings have been achieved by using alternative fuels and through strategic negotiations, while efficient management of the Captive Power Plant (CPP) has delivered significant savings. A streamlined approach to transportation and logistics has further reduced costs, boosting operational efficiency. Together, these initiatives enhance the Company’s cost competitiveness, ensuring long-term sustainability and high operational standards.

Ambuja Cements is focused on reducing operational costs through several key initiatives. To lower fuel costs, the Company is increasing the use of alternative fuels by installing chlorine bypass and additional shredding systems. For electricity cost reduction, WHRS systems are being installed and commissioned across all potential kiln systems. To decrease heat energy consumption, inefficient clinker cooler systems are being replaced with modern, high-efficiency ones to improve heat recuperation and reduce fuel use.

Electrical energy consumption is further reduced by installing high-efficiency drives and motors, along with conducting process audits, benchmarking, and process optimisation to enhance grinding and clinkering efficiency. Additionally, the Company is improving productivity by implementing advanced control systems and technologies like Vision Analytics to optimise kiln and mill operations.

of Downtime Saved in the Last 4 months through AI-based Predictive Maintenance

Reduction in Gypsum Cost by Using Low-Cost, High-Moisture Chemical Gypsum at Surat unit

To reduce costs, the Company explored the use of low-cost, high-moisture chemical gypsum. New sources of this gypsum were identified, and additional storage space was created to accommodate its irregular availability. To address its high moisture content, the gypsum was mixed with anhydrite powder to improve flowability, and air blasters were installed in the gypsum dump and main hopper to prevent jamming.

As a result of these actions, the Company successfully consumed 497 MT of zero-cost high-moisture gypsum in Q2 2024-25, replacing anhydrite gypsum. This initiative led to savings of ` 6.83 Lakhs, highlighting the tangible cost benefits of optimising material usage and supply chain adjustments.

of low-cost, high-moisture gypsum consumed

Mining

The Company's commitment to sustainable operations is demonstrated through efforts to improve equipment productivity, reduce environmental impact during mining activities, and optimise fleet operations by strategically negotiating and minimising stock rehandling.

Ambuja Cements’ Mine Management approach focuses on strict adherence to mining laws, regulations, and sustainability guidelines. The Company employs innovative practices to minimise environmental impact, such as blast-free, eco-friendly mining techniques at Ambuja Nagar and controlled blasting with electronic detonators at other sites. Dust-suppression technologies, covered conveyor belts and well-maintained haul roads are implemented to reduce pollution.

The Company also maintains green belts, engages with local communities, and upholds health and safety standards across all mining sites. Its comprehensive Mine Closure plan includes compensatory afforestation and rehabilitation, reflecting Ambuja Cements’ commitment to responsible and sustainable mining practices.