Natural Capital

Business-environment balance is a natural choice.

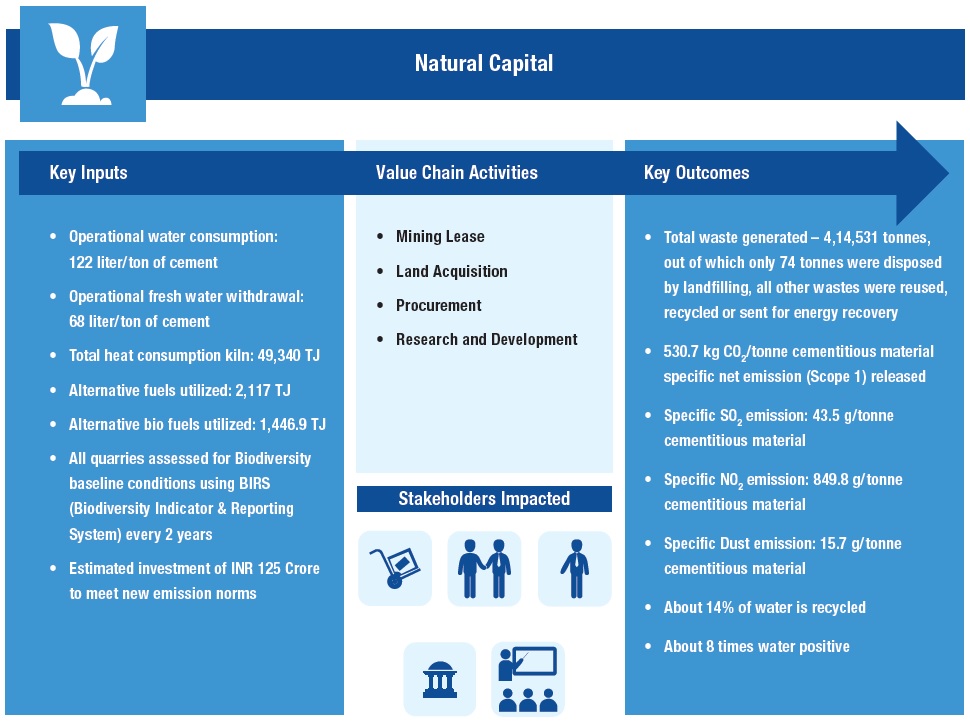

We understand that we operate in one of the most energy and material intensive industries and that we also hold the great responsibility to maintain a balance between our demand for the natural resources and the impact we have on the natural resource capital for the community and the future generations. We also realize the global pressure on natural resources and place high priority in managing our raw material requirement and sourcing practices. With this understanding, Ambuja has embarked on implementing a circular economy model in our operations by optimizing our supply chain and mining operations. Strategic focus is placed on use of alternative raw materials to substitute natural resources and extend the life of the quarries. Energy conservation, switch to the most economical fuel mix and emission reduction form an integral part of our business strategy. We have also made our commitments publicly available in our sustainability and climate change mitigation policies reflecting our commitment to sustainable development. We invest significantly in reducing our environmental footprint and in enhancing the positive contributions of our products and processes to the environment.

When nature comes full circle to reward.

Waste materials (both non-hazardous and hazardous) from other sources are resource for us. Ambuja used about 8.7 million tonnes of waste-derived raw materials and fuels such as fly ash, slag and biomass. About 0.3 million tonnes of alternate materials and wastes were used as fuels to achieve the thermal substitution rate of 5.36 %, replacing fossil fuels. In a major initiative to be a plastic-negative Company, we co-processed about 94,570 tonnes of plastic waste from the market and became more than two times plastic-negative (which means co-processed more than two times plastic wastes in Ambuja kilns than the plastic content used in the cement bags for packaging).