Our intellectual capital encompasses a wealth of ideas, technical expertise, process knowledge, and a consistent ability to innovate. It also includes intangible assets like our brand value and corporate culture, which have been instrumental in maintaining our position as market leaders. By efficiently utilising our intellectual capital and continuously enhancing our digital and technological capabilities, we are ensuring our readiness for the future. Throughout the year, we have reinforced our knowledge base through targeted learning and development initiatives for our employees. Additionally, we have leveraged our strength in innovation to generate new knowledge and develop sustainable products and construction solutions that align with a low-carbon future.

Stakeholders impacted

Stakeholders and investors

Dealers

Suppliers

Customers

Employees

Community and NGOs

Government and regulatory authorities

Construction professionals

Industry associations

Material issues addressed

- Customer satisfaction

- Sustainable construction

- Economic performance

Key risks addressed

- Maintaining market position

- Resource availability and price

- Cyber security

SDGs impacted

Capital-wise performance > Intellectual capital

Overview

As a flagbearer in technology adoption, we have solidified our position as industry pioneers by prioritising research and development efforts. Our commitment to innovation extends beyond introducing new and sustainable products and solutions; we also strive to optimise resource utilisation and drive decarbonisation within the cement industry. To enhance our competitive advantage in the market, we are expanding the implementation of digitalisation throughout our organisational value chain.

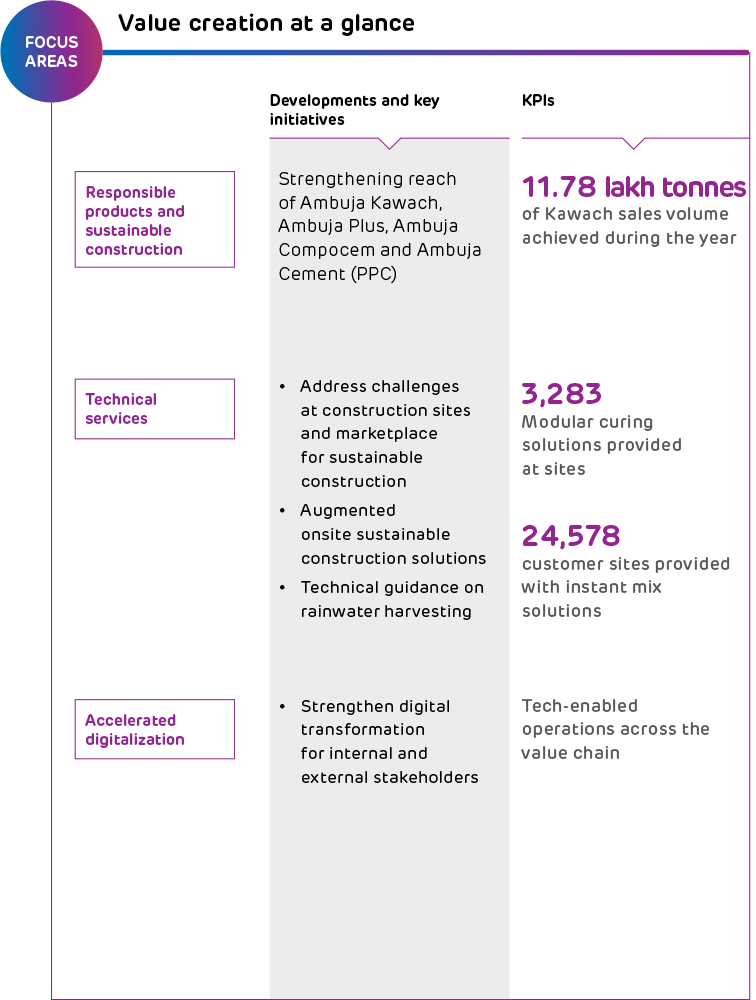

Sustainable and Responsible Construction Solutions

We take proactive initiatives to help reduce our carbon footprint, while enhancing our product quality and brand promise. Our products and services help our customers and construction professionals reduce their carbon footprint, manage maintenance requirements and cost of operations, making the projects greener and cleaner with lower environmental footprint.

During the reporting period, we continued to scale up our sustainable products and solutions.

- Launched in 2020, Ambuja Kawach has emerged as a preferred product for its unmatched attributes. To expand availability, we started supplying the product from four more plants – Bhatapara, Dadri, Ropar and Darlaghat.

- Ambuja Cool Walls, our green solution for walls, are made of pre-cast autoclaved aerated concrete with a special heat-barrier technology that helps keeping homes cooler during summer and warm during winters.

- Our blended cements portfolio, consisting of Ambuja Plus, Ambuja Kawach, Ambuja Compocem and Ambuja Cement (PPC), are now listed in the Green Product Catalogue of Green Rating for Integrated Habitat Assessment (GRIHA), a national green rating system of India co-developed by the Ministry of New and Renewable Energy, Government of India. Our products were evaluated based on the third party test results, benchmarks and environmental certifications etc.

Technical services

We have developed various products and solutions with ‘Ambuja Certified Technology’ to enable sustainable construction, which has become a key differentiator for the Company. Our Technical Services Team undertakes various initiatives to promote sustainable construction.

Our Instant Concrete mix proportion solution maximises the efficient utilisation of natural resources by optimising the proportions of aggregates, sand, and water in the concrete mix based on their specific properties. During the reporting period, we successfully implemented the Instant Mix Proportioning Solution at 24,578 customer sites. This solution has not only contributed to the creation of strong and durable concrete but has also resulted in significant water savings of approximately 30 million litres.

Our in-house developed Modular Curing solution, also referred to as the Zero Water Curing solution, provides an effective and efficient method for curing concrete slabs without the need for water. During this year, the Modular Curing Solution was implemented at 3,283 sites, resulting in significant water savings of approximately 39 million litres at construction sites. This innovative solution allows for sustainable curing practices while maintaining the quality and durability of the concrete structures.

Slab Supervision: Our team of technical experts provided technical guidance & supervision for slab casting on 31,698 customer sites

Our team actively promotes awareness and provides technical guidance to customers on implementing Rainwater Harvesting Solutions on their construction sites. This solution enables our customers to become self-sufficient in meeting their water demands. During this year, we extended Rainwater Harvesting guidance and solutions to 106 sites, resulting in a conservation of approximately 9 million litres of water annually.

Ambuja Knowledge Centre

The Ambuja Knowledge Centre was as a knowledge sharing platforms for architects and engineers. We have 18 such centres across the country to promote and educate construction professionals on sustainable construction and advanced material and techniques. We use our AKC platform to promote and educate about sustainable construction as well as advance construction material and techniques. Around 15,500+ Professionals were covered in various knowledge sharing activities through Ambuja knowledge Centre platform which includes physical and virtual modes.

sharing activities through Ambuja knowledge Centre

Accelerating digitalisation and innovation

With an aim to strengthen operations and improve our competitiveness, we are driving digitalisation initiatives across the following functions: Operational Excellence, Controls and Compliance, and Culture.

At Ambuja Cement, we believe that Digitalisation is a key driver of sustainable business growth. Over last few years, we have continuously adopted digital techniques and across its core business processes including sales, logistics, material management, manufacturing, control systems and technology operations.

Our digital transformation strategy aims at transforming the business processes and optimising the resources to achieve sustainable business growth while complying to various regulatory requirements. Our marquee digital initiatives include:

Cyber Risk Management – We have a comprehensive Cyber Risk posture management programme aimed at ensuring confidentiality, integrity, and availability of its critical business assets. All security operations are governed from an in-house, 24 x7 centrally operated Cyber Defence Centre. Our SOC has best in class cyber security solutions covering Brand Protection, End Point Security, Cloud workload protection, Perimeter security, Multi Factor Authentication, Data Protection & Encryption, Application Security, SIEM for OT & IT system monitoring and Cyber Incident Management.

Cloud First strategy – Strategically, we have adopted cloud first policy and all its digital assets have been migrated to hybrid public cloud platform to achieve high availability, agility, and operational efficiency. Cloud first strategy has provided the desired speed and agility to the business for sustainable business growth.

Centralised Command & Control on Adani’s Industry Cloud (aligned to Industry 4.0) – At Ambuja Cement, a comprehensive Digital Command & Control Centre is being setup to enable end-to-end visibility of the business processes and systems. This will enable real-time view of the Production, Demand, Sales, and Logistics under one umbrella. The C&C is a long-term strategic digital initiative to enable remote ‘exceptionbased interventions’ in decision making, based on the real-time market scenarios.

Advanced Mobile Platform – Our comprehensive mobile application platform and multiple applications have been launched to boost the sales, and marketing. Through mobile applications, our dealers, warehouse operators and customers can track the real time status of their orders and shipments.

AI/ML for Predictive Analysis – We have adopted Artificial Intelligence (AI) and Machine Learning (ML) based tools to predict demand, optimise production and to control the distribution. Diligent use AI and ML based logistics platform has given ACL a competitive advantage over other players in the market.