Efficient management of our manufacturing assets plays a crucial role in enhancing our operational efficiency, driving profitability, and sustaining our growth trajectory. Throughout the year, we remained dedicated to optimising our current facilities, implementing planned expansions, and investing in state-of-theart technologies. We are committed to sustainability and safety.

Stakeholders impacted

Dealers

Suppliers

Employees

Government and regulatory authorities

Construction professionals

Material issues addressed

- Capacity utilisation and current demand

- Land acquisition for mines and new operations

- Energy efficiency

- Compliance to regulatory requirement

Key risks addressed

- Market position

- Scarcity of natural resources

SDGs impacted

Capital-wise performance > Manufactured capital

Overview

Our manufactured capital comprises the tangible objects that facilitate our day-to-day operations and delivery of our products. This includes physical infrastructure such as our land, buildings, production plants, mines we have leased, heavy machinery and equipment fleet, furniture and fittings among others.

Development and efficiency

At Ambuja Cement, we continuously invest to strengthen our market position and evolve as a more efficient, cost-competitive and environmentally sustainable organisation. Key initiatives of the year include:

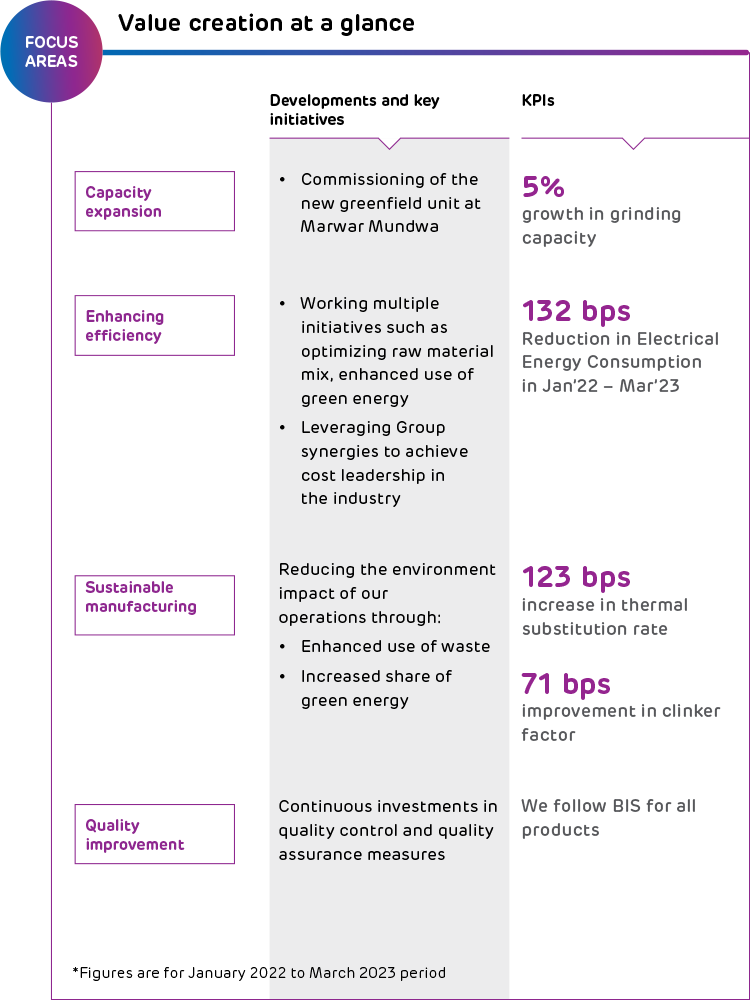

Capacity expansion

- We have set up a greenfield integrated plant with 3.0 MTPA clinker capacity and 1.8 MTPA cement grinding capacity at Marwar in Nagaur District of Rajasthan. Commercial operations commenced from September 2021 and installation of a Waste Heat Recovery System (WHRS) of ~ 14 MW capacity has been commissioned

- We are in advanced stage of placing commercial order for setting up 8 MTPA clinker unit at Bhatapara and Maratha (4 MTPA each) and associated Green field and brownfield grinding units of 14 MTPA.

Raw material security

-

To secure limestone needs of various cement plants

and to secure raw material for future requirements,

following limestone blocks were through

participating in auction:

- 3D-2, Harima-Pithasar Limestone Block – Ambuja Cements Ltd., in Rajasthan

- Sulahalli Limestone Block (CL) – Ambuja Cements Ltd., in Karnataka

- Uskalvagu Limestone Block – Ambuja Cements Ltd. in Odisha

- Mudhvay Sub Block-C Limestone Block – Adani Cementation Ltd.

- Devalmari Block at Maharashtra

- Dahegaon Gowari Coal Block in Maharashtra

- To meet future limestone requirement, we have invested `30.44 crore to purchase land and infrastructural developments across mines

- To secure our fuel resources, the earlier acquired coal block at Gare Palma sector IV/8 in Chhattisgarh through e-auction where operation has been commenced from October 2018 (open cast) and underground mining commenced from October 2021

- We have also acquired one coal block in Maharashtra. The necessary approvals and environmental clearance for above mining blocks are in progress. The land acquisition process is in progress, along with necessary infrastructure development

- To ensure adequate availability of dry fly ash, we have installed fly ash dryers/hot air generators in plants located in Rajasthan and Punjab with an investment of `120 crore

Energy

-

To minimise power costs and enhance the

use of green power, we had installated WHRS

across locations

- Cumulative 53 MW capacity at Marwar, Darlaghat and Bhatapara plants at a total investment of over `550 crore have been installed

- Cumulative 27.5 MW capacity at Ambujanagar and Maratha plants at a total investment of over `475 crore are in advance stage of installation

- Additionally, a plan is in place for utilisation

Logistics

To strengthen our logistical capability and to efficiently reach out to customers, a number of initiatives were taken such as optimisation of warehouse location, enhance share of direct dispatch and further exploration of sea routes, leveraging Group synergies.

Manufacturing performance

We adopt best practices in manufacturing of international standards. By implementing advanced technologies, optimising production processes, and ensuring quality control, we are enhancing operational efficiency, reduce costs, and minimise environmental impact. We are emphasising continuous improvement, innovation, and employee training to sustain superior performance and customer satisfaction. Some of the highlights include:

- Utilised around 13.68 million tonnes of waste derived resources (0.88 million tonnes is by Geoclean) in production, in line with our commitment of continuously reducing the usage of natural resources in manufacturing

Efficiency improvement

In order to emerge as one of the most cost-competitive cement manufacturers in the country, we make continuous investments in the areas of clinker factor reduction, energy efficiency, raw material mix and fuel mix optimisation, power mix and enhanced use of alternative fuels and raw materials in manufacturing.

Plant efficiency

- Reduction in electrical power consumption achieved through optimisation of grinding media charging and optimisation of grinding aid consumption

- Installation of new high momentum and low NOx burner

- Up-gradation of existing cooler

- Baghouse filter bag replacement with low drag to reduce the pressure drop, leading to reduction of SEEC (Specific Electrical Energy Consumption) at Rabriyawas

- Installation of IKN Cooler to reduce heat consumption and improve efficiency at Bhatapara

- Reduction in SHR (Station Heat Rate) and auxiliary power consumption by replacing SJAE with vacuum pump for STG3

Cost efficiency

- Maximisation of Wet Fly Ash (WFA) and Conditioned Fly Ash (CFA) usage to reduce overall fly ash cost

- Replacement of 50% traditional High Speed Diesel usage with pyrolytic oil at the time of cold kiln startup

- Maximisation of alternative fuels and raw materials to reduce fuel cost

- Optimisation of raw mix in fuel to reduce overall cost of cement

- Use of molecule-based grinding aid to reduce procurement from vendors

- Maximum utilisation of fly ash to reduce clinker factor

- Variable Frequency Drive (VFD) Installation in In-line Calciner (ILC) Coal Firing Blower to save 480 kWh per day

- Kiln Master and Mill Master (Advanced Process Control) commissioned for better mill performance

Committed to Reduce Energy and Power Consumption

Our optimisation efforts during the reporting period resulted in the following:

- Optimisation of kiln operation to reduce Specific Thermal Energy Consumption (STEC) from 746 kCal/kg of clinker to 742 kCal/kg of clinker in ACL.

- Optimisation of kiln and cement grinding mill to reduce power consumption reduce from 73.47 to 72.59 kW/t cement.

Capital-wise performance > Manufactured Capital

Product quality management

Ambuja Cement stands as an unrivalled symbol of impeccable product quality. With a steadfast commitment to excellence, our quality parameters are rigorously upheld, meticulously monitored, and continuously refined to elevate the overall Product Quality Index (PQI). From stringent quality control measures to relentless pursuit of improvement, we set the gold standard in product quality, reinforcing our position as a trusted industry leader. Our product quality monitoring strategy includes daily testing on defined quality parameters; three-day and 28-day measurement of coefficient of variations, clinker quality assessment, customer satisfaction, bi-monthly product benchmarking, bi-monthly application-oriented product testing; monthly testing of random market samples and monthly assessment of bag quality index.

We are compliant with all the statutory requirements as mandated by the Bureau of Indian Standards (BIS) and all weights and measures norms. As a statutory compliance, our bags display the contact details for customers to communicate any complaint, observation and query.

To ensure consistent results, we follow the round robin test methodology to identify issues and improve upon the same. Further, following actions are being taken up:

- Productivity research for increased efficiency in use of resources

- Development of application oriented cements with decreased CO2 emissions

- Development of cements tailored for specific market clusters and application segments

- Development and manufacture of composite cement with improve concrete performance

- Development of new products or developing new methods of evaluation and characterisation

Key initiatives to improve overall process/product quality during the year:

- Installed robotic lab for real time quality monitoring and control of cement manufacturing at Marwar

- Installed Cross Belt Analyser for real time quality check of input limestone from mines

- Implemented Technical Information System (TIS) for production and Laboratory Information Management Systems (LIMS)

- Use of molecule-based grinding aid to improve the strength of cement

- Optimised SO3 across location to improve strength

- Qualitative and quantitative identification of clinker phases for strength optimisation using X-ray Defraction Meter (XRD)

- Quality benchmarking exercise conducted for different market clusters

- Blended cement through innovative processing utilising industrial by-products for improved quality Performance of our plants

Supply chain and logistics

During the year, fuel prices continued to remain high. Considering the challenges, we took the following initiatives:

- Total freight cost reduced by `64 /Ton (`1,160/T in Jan’22 to Mar’23 vs. (`1,224/T in 2021) despite headwinds of HSD price increase ~2% & railway busy season charge (+15%) from Oct’22

- Improved the synergy between Ambuja and ACC plants to gain on logistics cost saving

- PAN-India warehouse network optimisation increased direct dispatch to customer by 4%

- Integrated UDAAAN Project for logistics cost Rationalisation rolled out to unlock group synergies & leverage technology

Mining

All our integrated cement plants are associated with captive limestone mines for securing major raw material.

We are optimising mine utilisation through the following ways:

- Maximise the use of alternative and waste derived materials in the process

- Adopted ZERO Waste mining policies

- Proper blending of low grade and high-grade material for optimisation of resources as well as maximising life of mines

- Eco-friendly mining with no blast technique by deploying surface miner in coastal areas

- Conservation of mineral, water and other natural resource materials

- Adopting safe practices in each mine during development and operation

- Environment friendly mining operation by deploying mining equipment with minimum exposure of workers to health and occupation hazards