Stakeholders Impacted

Investors and Shareholders

Channel Partners

Suppliers

Customers

Employees

Community and NGOs

Government and Regulatory Bodies

Construction Professionals

Industry Associations

Material Topics

- Customer Satisfaction

- Sustainable Construction

- Economic Performance

Focus Areas

Developments and Key Initiatives |

Key Performance Indicators |

|

|---|---|---|

Responsible

|

Strengthening reach of Ambuja Kawach, Ambuja Plus, Ambuja Compocem and Ambuja Cement |

9.46 lakhs tonnes

Kawach sales volume achieved during the year |

Technical

|

Building awareness about sustainable construction practices Augmented on-site sustainable construction solutions Providing technical guidance on rainwater harvesting Maximising use of modular curing and instant concrete mix solutions |

2,327

Modular curing solutions provided at sites ~51 million litres

Conservation of water through modular curing, and instant mix concrete proportioning solutions |

Accelerated

|

Digital Plants of Future Commissioning of Command and Control Centre Digitalising logistics and fleet management Enhancing the digital sales platform |

Tech-enabled operations across the value chain |

Overview

As a technology leader, the Company has solidified its position by prioritising research, introducing sustainable products, optimising resource usage, and driving decarbonisation in the cement industry. Ambuja Cements is expanding digitalisation throughout its organisational value chain to enhance its competitive edge.

Sustainable Construction Solutions

The Company initiates measures to minimise its carbon footprint while elevating product quality and upholding the brand promise. The Company’s offerings help its customers and construction professionals lower their environmental impact, manage maintenance, and reduce operational costs, ultimately creating greener and cleaner projects. Throughout the reporting period, Ambuja Cements continued expanding its network and reach of sustainable products.

The Company’s products, such as Ambuja Kawach, Ambuja Plus and Ambuja Compocem, are listed in the Green Product Catalogue of Green Rating for Integrated Habitat Assessment (GRIHA), a national green rating system for India co-developed by the Ministry of New and Renewable Energy, Government of India. These products were evaluated against third-party test results, benchmarks, and environmental certifications. The Company strives to support the needs of Individual Home Builders (IHBs) effectively through timely distribution of products. Optimising its warehouse operations, the Company strives towards sustainable work practices.

Sustainable Construction Initiatives

During the year, the Company promoted sustainable construction and empowered Individual Home Builders (IHBs) during the construction through:

- Ambuja Certified Technology: Under the 'Sapno Ka Ghar' project with ACT' initiative, the Ambuja or ACC Certified Technology is utilised, guided by registered contractors or engineers affiliated with Ambuja Abhiman or ACC Atoot Bandhan loyalty programmes. Additionally, Star Rating ACT Certificates incentivise contractors and dealers to drive ownership and increase the number of ACT-converted sites, contributing to the project's success and fostering growth with goodness in the region.

- In-house Modular Curing Solutions: To offer effective and efficient curing methods for concrete slabs, the Company has developed revolutionary modular curing solutions, the aptly named zero water curing solutions, for reducing water usage during the process. In the current reporting year, the Company’s modular curing solution has been successfully implemented at 2,327 construction sites, resulting in a remarkable conservation of approximately ~28 million litres of water.

- Instant Mix Concrete Proportioning Solution: Based on their properties, the Company’s instant concrete mix proportioning solution optimises using aggregates, sand, and water in the concrete mix. In FY 2023-24, this solution was delivered to 18,081 customers, leading to the conservation of approximately ~23 million litres of water.

- Ambuja Abhimaan: Ambuja Abhimaan uses the Ambujacertified technology to acknowledge, strengthen and reinforce ties with loyal partners. With this contractor loyalty programme, Ambuja Cements aims to empower and encourage contractors to make strong homes using Ambujacertified technology. So far, 2.49 lakhs contractors enrolled in Ambuja Abhimaan.

Ambuja Knowledge Centre (AKC)

Ambuja Knowledge Centres (AKCs) serve as knowledge-sharing hubs for architects and engineers at 18 sites across India. These centres focus on educating construction professionals about sustainable construction and use of advanced materials and techniques, held through various physical and virtual knowledge-sharing activities, reaching a substantial audience of 20,000+ professionals.

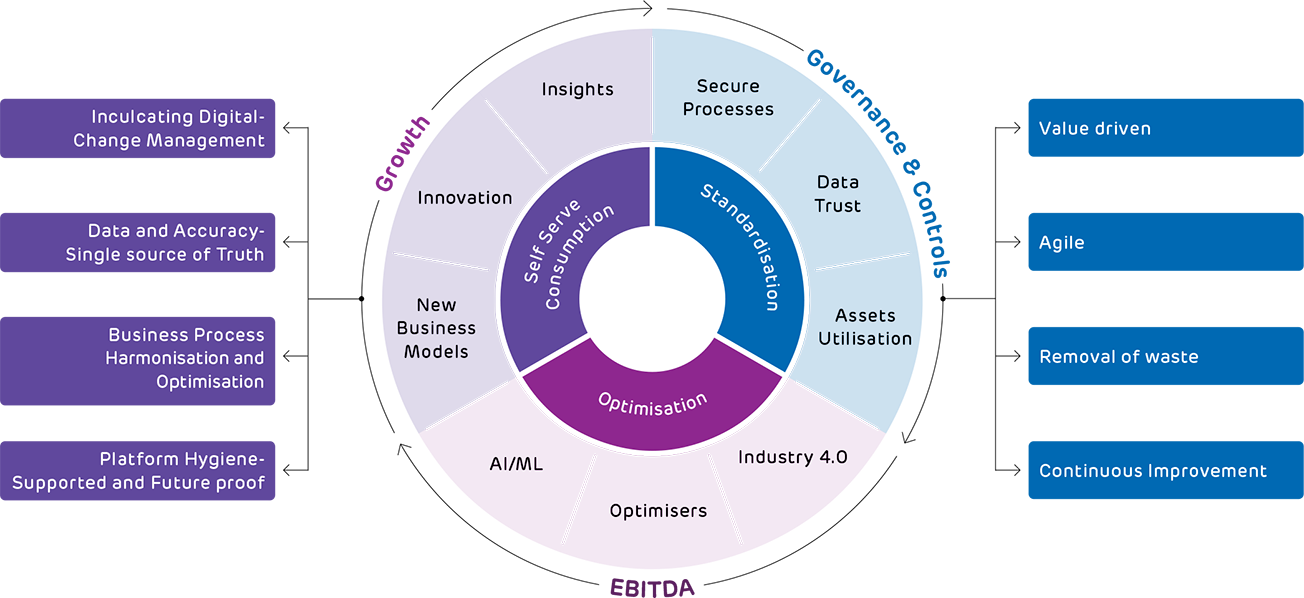

Digitalisation

As a responsible adopter of digitalisation, the Company has integrated various digital tools and techniques into its core business operations, spanning sales, logistics, material management, manufacturing, control systems, and technology operations. Ambuja Cements' well-defined digital transformation strategy aims to revolutionise these processes, optimising resource allocation for sustainable business growth while ensuring compliance with regulatory requirements.

Ambuja Cements' digital transformation endeavours align with Industry 4.0, and substantial investments underscore its dedication to enhancing its position in the Indian cement manufacturing sector.

Initiatives towards Digitalisation

Plants of Future

Ambuja Cements is implementing the 'Plants of Future' programme to digitally transform manufacturing processes to improve production quality and reduce costs. Initiatives include incorporating robotics for automation, fully automated weighbridge operations, in-plant automation, automated quality testing for cement bags, robotic process automation for plant shutdown management, and drones for maintenance and other manufacturing procedures.

Logistics Transformation

The Company is implementing advanced logistics and fleet management, ensuring real-time vehicle tracking and enhancing delivery promptness and efficiency. It optimises logistics expenditure, contributing to improved profitability.

Digitalised Command and Control Operations

In phase 1 of the Command and Control programme, the Company has developed CNOC - Cement Network Operating Centre to view sophisticated digital dashboard for crucial business processes like manufacturing, sales, logistics, HR, and finance. These virtualised key performance indicators (KPIs) and dashboards facilitate real-time performance monitoring across various regions, brands, facilities, and markets, enabling informed decisions to optimise production, sales, and EBITDA margins.

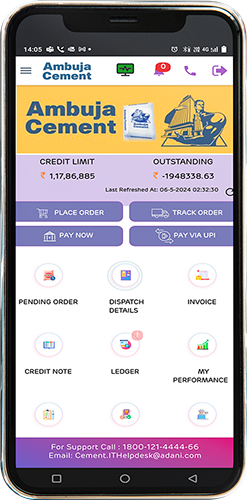

Unified Sales Platform

The Company's cutting-edge digital sales platform provides a consolidated view of real-time transactions across channel partners and construction professionals like Architects, Engineers, and Contractors. This platform empowers the Company with accurate demand forecasting and intelligent pricing strategies, giving us a competitive edge. The platform also seamlessly integrates accounting systems with SAP, informing it about inventory and other business transactions.

Advanced Digital Technologies – AI & Generative AI

Ambuja Cements is implementing extensive use of artificial intelligence (AI) and generative AI in its operations. The Company has gained a market advantage by adopting AI-based solutions, anticipating and optimising production and distribution, and effectively mitigating associated risks. The Company is piloting Gen AI in its legal and procurement functions to increase operational efficiency

Enterprise Security and Risk Management

Cybersecurity is the Company’s core focus, with significant investments over the reporting period to enhance its cyber risk posture. Ambuja Cements has implemented a comprehensive cybersecurity programme ensuring confidentiality, integrity, and availability of critical business assets. The Company’s security stack includes advanced tools in compliance with ISO and NISTbased security architecture and governance framework. The Company’s security operations centre utilises cutting-edge cybersecurity solutions, including brand protection, endpoint security, cloud workload protection, perimeter security, access management, multi-factor authentication, data protection, encryption, vulnerability management, and application security. An in-house, 24/7, centrally operated cyber defence centre handles the Company’s security operations.

AmbujaHelp – Ambuja Cements' Digital Enabler for Home Builders

Ambuja Cements innovated a digital platform, ‘AmbujaHelp’, with an aim to revolutionise the construction journey for Individual Home Builders (IHBs) and build impactful connections with dealers across the nation. It is designed to support, guide, and empower IHBs and dealers, ensuring quality customer service.

The digital platform offers the ‘Home Building Guide’ providing expert knowledge on home building and helping IHBs to find authorised dealers. It has an in-build cost calculator to offer precise cost and material estimation. Ambuja Cements' range of products are also available through the digital platform.

![]() Case Study

Case Study

Under 'udAAAn, Ambuja Cements has embarked on several initiatives including digital to revolutionise its approach to innovation and automation.

- Launched the ‘Think Digital Championship’ to promote digital adoption, innovation, collaboration and employee engagement in digital programmes

- Improved the Company’s cybersecurity

- Launched an application to report end users’ requests and issues

- Actively invested in automation and robotics to save around 79,000+ man-hours

- Inaugurated state-of-theart centre of excellence and cutting-edge lab for concrete products in Chennai