10. Health and Safety.

Step-up in Health and Safety Performance

The ‘Zero Harm’ initiative continues to remain at the core of our Health and Safety programs and awareness. In 2019, we have dealt with health and safety related challenges in a manner that demonstrates our ‘Safety First’ approach. We witnessed one on-site incident during the year, which proved to be fatal in nature. The Company has learnt from this unfortunate incident and we endeavor to ensure implementation of required measures and procedures to prevent repetition of such an incident. This aside, we witnessed improvements across our leading and lagging indicators. Our gradual progress towards ‘Zero Harm’ can be witnessed through 35% reduction in Total Incident Frequency Rate (TIFR) and 31% reduction in Lost Time Injury Frequency Rate (LTIFR), compared to previous year. The count of on-site injuries, including first aid, has gone down by 27%. Even on the road safety front, we witnessed 9% decline in number of off-site road incidents.

Challenges

The Company encountered the following challenges in 2019:

• Operational discipline on the frontline with respect to compliance of rules governing safe conduct

• Introducing a robust ‘Permit to Work’ system across locations

• Implementation of ‘Fatality Elimination Controls’ on ground

• Maintaining our medical emergency response capability at an optimum level round-the-clock, especially in remote locations

• Driving techniques and compliance to minimum vehicle specifications in our logistics chain, to minimize and eliminate untoward incidents and injuries

Strategy

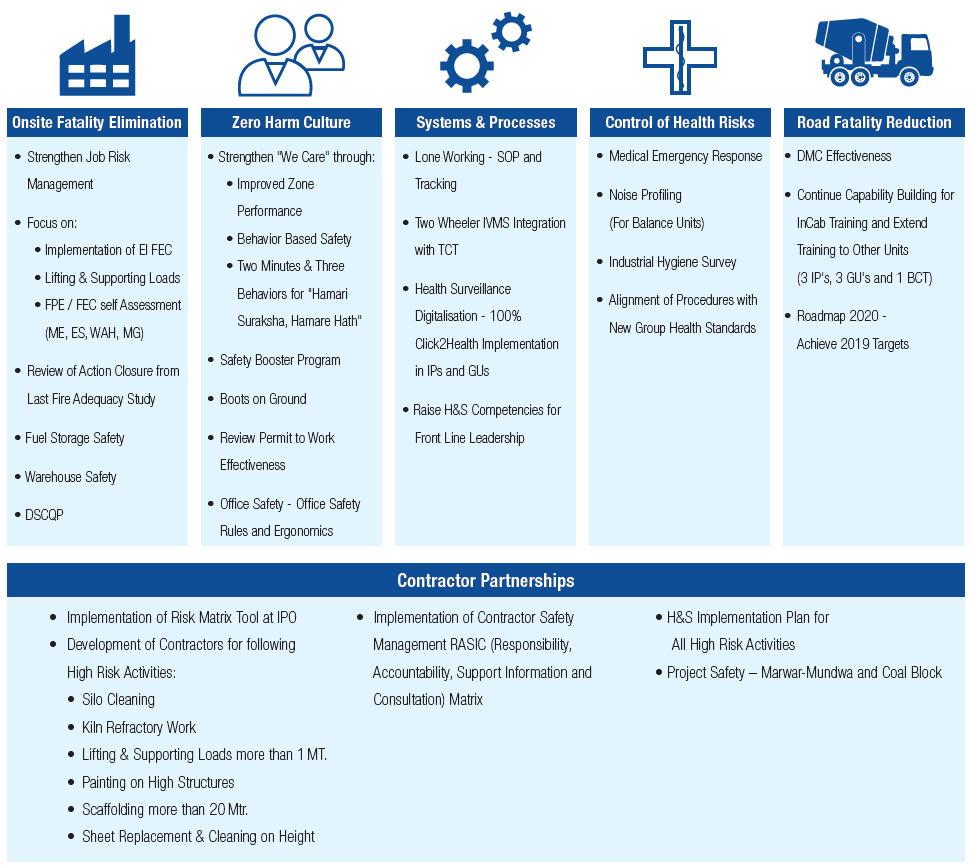

The Company executed its health and safety strategy based on the five pillars of Onsite Fatality Elimination, Zero Harm Culture, Systems & Processes, Control of Health Risks and Road Fatality Reduction.

The strategic initiatives were adequately supported by:

• Monthly performance monitoring at unit and corporate levels

• Focus on learning from incidents and action closures

• Campaigns / self-assessments on:

• Minimum Safe Behaviors

• Don’t Walk Past

• Lifting & Supporting Loads

• Permit to Work

• Mandatory Safety Release #1 (Hot Meal)

What We Achieved

Highlights of our on-site Health and Safety performance are as under:

• Successful accomplishment and adherence to ‘Zero Harm’ initiative principles in 4 manufacturing units (Surat, Dadri, Panvel and Mangaluru)

• 3 manufacturing units (Surat, Dadri and Mangalore) achieved more than five ‘Lost Time Incident (LTI) free’ years

• 13 additional manufacturing units were LTI free in the year 2019

• 27.65% reduction in on-site recordable injuries

• 19.40% increase in leading indicators, compared to 2018

On the road safety front, positive strides have been made with effective use of technology and data analysis coupled with practical driver assessment, resulting in 39% drop in incidents with a corresponding reduction in injuries by 46%. Highlights on this front include the following:

• 5,025 In-cab assessments (on-road practical) completed by truck drivers and company-owned four-wheeler drivers

• 2,188 in-vehicle monitoring systems (IVMS) installed in controlled fleet trucks. This has facilitated blanket monitoring of driving behavior and pattern when materials and end-products are being transported

• 506 in-vehicle monitoring systems (IVMS) installed in two-wheelers (marketing) and integrated with Transport Analytics Center (TAC) for tracking driving behaviour and pattern