Our HR management philosophy

revolves around empowering the

employees to make them more

productive, efficient and integral to

the organisation. We aim to strike a

balance between the achievement

of business goals and nurturing the

talent pool available to strengthen the

organisation’s competitive advantage.

We maintain a collaborative,

inclusive, non-discriminative and

safe work culture, and provide equal

opportunities to all employees. We

have a ‘Zero Tolerance’ policy towards

sexual harassment at the workplace

based on the applicable law. Our

Codes of Business Conduct lays down

acceptable professional behaviour

expected from our internal and

external stakeholders.

Employee benefits

Contribution to Superannuation Fund,

Provident Fund (PF), Employees’

State Insurance Corporation and

Labour Welfare Fund form our defined

contribution plan towards employee

benefits. Retirement benefits such

as gratuity, is considered as defined

benefit obligations; they are provided

based on actuarial valuation, using the

projected unit credit method. Postretirement

medical benefit is now

completely funded by beneficiaries.

Death and disability benefit is as per

the insurance policy. For most of the

employees, the Provident Fund is

managed by the Employees Provident

Fund Organisation (EPFO). Some

employees are part of the exempted PF

trust of Ambuja. Healthcare, disability,

invalidity coverage, life insurance,

and medical benefits are available

to employees. Superannuation is

not available to some categories of

Full-time employees (FTEs). All these

benefits are offered irrespective of

location. Women employees are

entitled to maternity leave as per

The Maternity Benefit (Amendment)

Act, 2017. An employee can avail

of maternity leave for a continuous

period of 26 weeks, or opt for two

13 week segments, divided between

the pre-natal and post-natal period

as per her convenience. This benefit

can be availed of up to a maximum of

two children. In 2020, seven women employees availed maternity leave; six

of them remained employed for the rest

of the year after resuming work, and

one is still on leave. A minimum of one

month notice is provided to employees

and their elected representatives prior

to the implementation of significant

operational changes that could

substantially affect them. This is

specified in the Industrial Relations

Act, 1947.

Employees who spend more than

a decade with the organisation are

felicitated with ‘Long Service Awards’.

Local minimum wage rules are

followed, and employees are paid

above the local minimum wages.

The ratio of the standard entry‑level

wage as compared to the local

minimum wage at significant locations

that include all our operating plants

is 1:1. Merit is the main parameter

for recruitment, but preference is

given to local hiring. We are an equal

opportunity employer providing equal

remuneration for women and men.

The ratio of the average basic and total

salary of women to men is 1.17:1 and

1.14:1, respectively management level

roles and 1:1 for the entry level average

total salary, considering all locations of

our operations.

We have recognised trade unions

affiliated to INTUC/AITUC/BMS,

representing blue collar employees at

different locations. Ambuja Cement

respects freedom of association

and allows its employees to join an

independent trade union. Out of our

total permanent workforce ~30%

employees are covered by collective

bargaining agreement.

Effective talent acquisition

We have in place campus hiring

programmes to recruit engineers and

management trainees to ensure a talent

pipeline that can be developed further

to accelerate our growth. During the

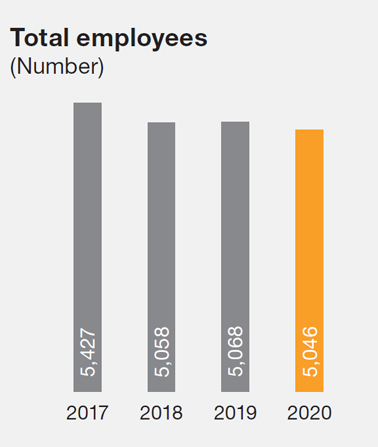

year, we recruited 142 new employees,

of which 9% are women.

Learning and development

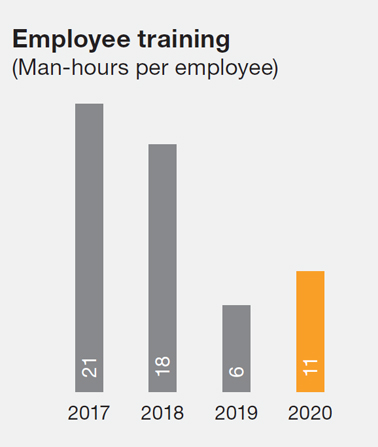

We try to constantly improve employee

learning and development activities.

The training needs and performance

gaps identified during the appraisal

process serve as the basis for formulating training and development

programmes for employees.

The ACC ACL Leadership Academy

(AALA)—a joint academy of ACC and

Ambuja Cement, started in 2012—

and Techport (for technical trainings)

provide leadership as well as functional

trainings to employees for developing

capability and competence. Apart from

classroom and on-the-job trainings,

we also focus on virtual e-learning

trainings and webinars for a wider

coverage on different topics while

enabling employees to learn at their

own pace and place.

Being part of the LafargeHolcim

Group, we provide our employees

with international exposure through

short-term projects and long-term

assignments.

Initiatives in 2020

Owing to the pandemic, the learning

programmes in 2020 were designed

around the use of digital technology.

Learning became an essential tool

of employee engagement and we

partnered with various internal experts

and functional heads to deliver these.

The learning programmes were

delivered through a three-pronged

approach:

- A total of 702 training programmes

were conducted during 2020

including physical and virtual

sessions on functional skill

development, soft skill development

and other modules relevant

for management and personal

development

- Other organisation-specific learning

programmes driven by the function

heads

These sessions utilised the online

meeting platform, along with the

in-house learning experience platform,

Super Assisted Intelligent Learning

(SAIL). SAIL is an application which

works not only as a repository for

programmes conducted, but also

for content creation, curation and

e-learning.

As per the business and training need

analysis, we are running certification

programme, role-based programmes

and expert development initiatives:

Plant-specific programmes

We run some specific programmes

to achieve consistent operations,

standard maintenance within the

plant and across the plants between

operators, engineers and technicians

in order to achieve sustainable

high performance.

Programme objective

- Consistently achieve operational

and maintenance targets by having

reliable operators, engineers and

managers who perform well and in

a safe manner

- Achieve sustainable high

performance in our plants

- Standardised maintenance

operation within LafargeHolcim

Group standards on operation

and safety

The following programmes were

initiated:

- Control room operator certification

- Walk-by inspector certification

- Process engineer certification

- Preventive maintenance engineer

certification

- Expert development initiative on

critical skills

- Leveraging technology—remote

troubleshooting and training

Talent management

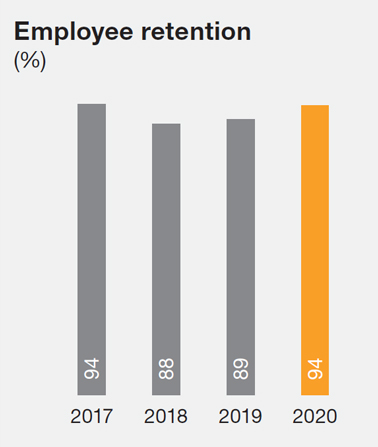

Our focus on nurturing talent with care

and a fair remuneration policy has

helped in developing a strong sense

of ownership among our employees.

Structured talent reviews, supported

with Individual Development Plans

(IDPs) and cross-functional and

cross-location assignments have

resulted in a healthy talent intake.

We introduced a new performance

structure that defines Profit & Loss

Accountability.

We initiate continuous dialogues

with our employees for their

feedback on deliverables, resulting

in better performance management.

Our dynamic objective setting, which

periodically translates the business

objectives into team and individual

contributions, helps in driving better

employee productivity. Together

with our periodic inputs that incite

merit increase, and bonus benefits,

we are helping strengthen our

employee output.

People for Tomorrow is our

LafargeHolcim Group initiative to

identify leading talent at our plants,

close competency gaps and manage

succession. It helps to ensure that we

have the right people, in the right role,

with the right competencies, at our

industrial sites.

Shaping behaviour at work

We follow the Kirk Patrick evaluation

methodology for findings the results

of our training programmes, which

enables us to assess and shape

employee behaviour along three

levels— Level 1: Reaction, Level 2:

Learning, Level 3: Behaviour change,

and Level 4: Results of the training

(applied for few trainings).

Level 1 and Level 2 behaviour were

assessed through knowledge‑based

programmes, largely in the large

webinar category. For Level 3

assessment, action learning projects

were conducted to assess whether

employees can convert their learning

into action. Level 3 evaluation was

initiated for a host of programmes,

including successor development

programme, health and safety and

technical trainings. The method

helped us measure how a training has

influenced behaviour and how this

is applied on-the-job. We used this

method to assess dealers following

the completion of the ‘New Dealer

Appointment’ training.

Training programmes imparted in

2020

(Physical and Online)

702

Developing a leadership pipeline

We invest proactively in training

initiatives for leadership development

to create a robust leadership pipeline

to drive the long-term growth objective

of Ambuja Cement. We focused our

leadership development initiatives

during the year around our Strategy

2022. We directed our leadership

programmes on health, cash and cost

to combat the change in the business

environment. The focus was on the

following:

- Build own resilience in managing

the pandemic: Our focus areas

were working with emotional

intelligence, managing team

motivation and managing dealer

relationships during the lockdown

- Build resilience as a team:

Grooming dealers, appointing new

dealers, honing cross-functional

skills, working and developing

stronger customer relations were

part of this initiative

- Build resilience as a business:

Negotiating with cash and cost,

lean thinking, reducing cost of

power and fuel, working with net

zero mandates were some of the

topics discussed

- Others: First time managerial skill

development initiative was also

taken up as an extension of the

leadership development programme

Succession planning

Key senior positions at Ambuja

Cement are now being increasingly

filled internally. Our Sustainable

Talent for Enhanced Performance (STEP) programme duly complements

our talent management model

for succession planning of senior

management.

We have created a structured talent

review and succession planning

process that assesses people on

defined matrices and plots them in a

nine-box performance and potential

matrix. Based on the outcome of

the matrix, the high-potential (HiPo)

candidates are assessed on their

preparedness and readiness to take on

higher-level roles.

The identified successors undergo

customised development programmes

to prepare them for the higher-level

roles in the organisation.

We have a pool of ready successors

who will drive our growth strategy over

the next three to five years.

Industrial relations

At Ambuja Cement, we believe that the

interests of our employees and those

of the Company are inseparable. With

this principle in mind, we engage with

our employee unions. On almost all the

occasions, a negotiated settlement/

understanding is reached in a

win-win manner.

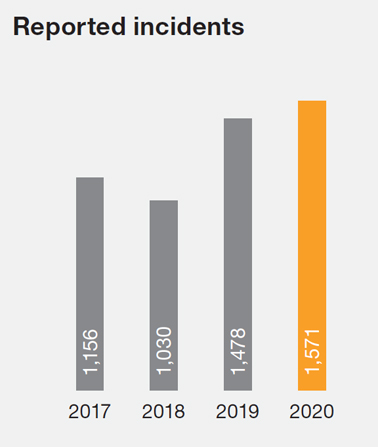

Occupational health and safety

Health and safety (H&S) remains one

of our core focus areas and we have

worked to make health and safety

improvement a way of life at Ambuja

Cement. The year 2020 was the final

year of our three-year H&S Strategy in

order to take our performance in this

function to a new level. We had put

in place the right systems where they were needed and focused on better

implementation rather than introducing

new initiatives. Our H&S improvement

deliverables for 2020 were built

around the theme, ‘Consolidate and

Strengthen As Is’.

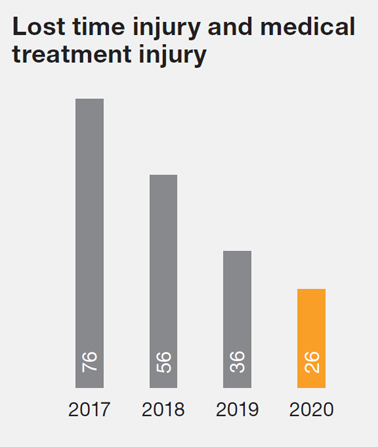

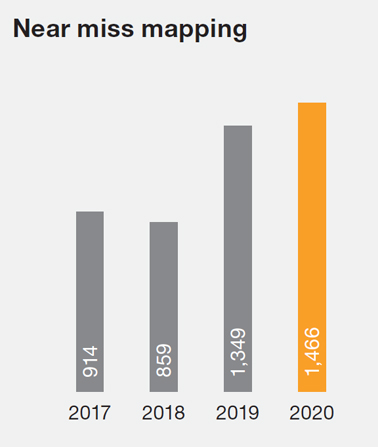

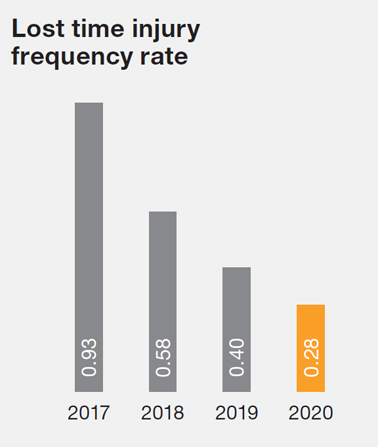

Despite the onset of the pandemic,

we were able to achieve a year of zero

onsite and offsite fatality with 30.3%

reduction in LTIFR. Road injuries also

reduced by 56.5%.

Key challenges to H&S in 2020

The biggest challenge to operations

in 2020 was the pandemic. We moved

with speed and learnt to operate in a

COVID-19 environment, where we had

to take this as one of the risks without

losing focus.

Some of our key focus areas are the

following:

- Institutionalising operational

discipline on the frontline, especially

with regard to compliance of rules

that govern safe behaviours

- Ensuring a robust permit to work

system across locations

- Implementing our fatality elimination

controls on the ground

- Maintaining our medical emergency

response capability at the required

level continuously, especially at

remote locations

- Ensuring acceptable driving

behaviours and compliance with

minimum vehicle specifications in

our logistics chain to reduce both

incidents and injuries

We focused on five pillars in our H&S process

| Onsite fatality

elimination |

Zero harm

culture |

Systems and

processes |

Control of

health risks |

Road fatality

reduction |

- Zero tolerance for

non-compliance

- Focus on leading

indicators

- Minimise repeat

incidents

- Strengthening job

risk management

– HIRA, PTW and

MOC

- Implement mobile

FEC

- Establish DSCQP

baseline and

implement Group

process

- Ensure silo

cleaning

capability

and process

compliance

|

- Greater leadership

visibility in the

field – Boots on

Ground

- Sustain ‘We Care’

through focus on

‘two minutes and

three behaviours’

and behaviourbased

safety

- H&S leadership

workshop for

cluster and unit

top leadership

- Step up H&S

competencies at

all levels

- Improve incident

investigation

capability and

capacity

- HSMS

implementation –

Marwar Mundwa

and underground

mine in coal block

|

- Digital

transformation –

integration with

iCare 2.0

- Strengthen

assurance around

permit to work

system, HSIP

implementation at

unit level, action

closure for crossand

intra-plant

audits

- Raise process

safety

management

awareness and

competency –

pilot programme

for Ambuja

Cement

- Pre-start up

safety review

implementation

- Review and

revitalise railway

safety

- Emergency

response

|

- Establish in-house

baseline and

complete survey

for remaining units

- Reduce dust

exposure through

control of fugitive

emissions, review

of efficacy of

existing hierarchy

of controls at

packing plants

and better

housekeeping

- Noise-specific

control plan

- Health

surveillance

digitisation

- Reduction of

manual handling

at warehouses

|

- 95% controlled

fleet through

monitored iVMS

- 90% controlled

fleet drivers

trained in Incab

- Effective

implementation

of rewards and

recognition and

consequence

management

- Minimum vehicle

specification

|

iVMS - In-Vehicle Monitoring System, HIRA - Hazard Identification and Risk Assessment, PTW - Permit To Work, MOC - Management of Change,

FEC - Fatality Elimination Control, DSCQP - Design Safety and Construction Quality Programme, HSMS - Health & Safety Management System,

HSIP - Health & Safety Improvement Plan

This plan was supported throughout

the year by:

- Compliance through visible frontline

leadership – Boots on Ground

- Strong mitigating measures against

COVID-19, including medical

emergency response

- Monthly performance monitoring at

unit and corporate level

- Remote audits and

self assessments on HSMS

implementation at all units

- Campaigns/waves on:

- - Housekeeping

- - Permit to work

- - Machine guarding

- - Working at height

- Sharing and replication of best

practices

- Timely closure of actions from

audits, process safety related

self-assessments and structural

inspections

Achievements in 2020

Our cohesive efforts across all sites

on operational discipline, systems and

processes, learning from incidents, and

more visible leadership presence in the

field (Boots on Ground) have helped

deliver stupendous results in 2020.

We even registered a 2% increase in

man-hours from 2019.

Highlights of our onsite H&S

performance:

- Completed the year with zero harm

in six units Surat (Gujarat), Dadri

(Uttar Pradesh), Kochi (Kerala),

Roorkee (Uttarakhand), Dirk India

Private Limited (DIPL) and coal

block

- Achieved more than six years of

Lost Time Injury (LTI) free in two

units (Surat and Dadri)

- Recorded a year of LTI free in 13

other manufacturing units

- Reported 14.28% reduction in total

onsite recordable injuries compared

with 2019

Road safety

We have also progressed well on road

safety, despite the impact of COVID-19,

especially on counselling drivers and

practical trainings. Key achievements

during the year in this space are as

follows:

- Reported 8.5% drop in logistics

related incidents

- Completed 1,891 Incab

assessments (practical on the

road) covering truck drivers and

company-owned four wheeler

drivers

- Installed 853 iVMS and 567 voice

boxes in controlled fleet trucks

for better coverage of driving

behaviours

- Achieved 10% increase in share

of safe km by two wheelers in

marketing vis-à-vis 2019

Man-hours of safety training

imparted in 2020

28,650

Conflict management

Our operating mining sites are not

located adjacent to indigenous

peoples' territories. We address issues

revolving around local communities

(land acquisition and dust emission)

through a consultative process and

purchase land through negotiations.

There were no strikes or lockouts at our

mines during the reporting period.

Protecting human rights

We have stipulated our human rights

policy in our Code of Conduct and

Business Ethics applicable to all

employees, vendors and suppliers.

We also stringently follow the

LafargeHolcim Group’s Directive on

Human Rights. Our commitment to

human rights is also reinforced by our

Group’s participation in the UN Global

Compact (UNGC), support for the Code

of Business Conduct for Suppliers, and

our CSR Policy.

A proactive comprehensive risk

assessment is undertaken across our

operations through Site Specific Impact

Assessments (SSIA), wherein each

operational site is assessed at least

once in a three-year cycle for potential

human rights risks and opportunities.

During 2020, SSIA could not be

conducted on site to avoid exposure

of employees and other stakeholders

with potential health hazards. Besides,

we continued to review the process of

the human rights compliance of our

plants, joint ventures and subsidiaries

remotely. Our JVs and subsidiaries

provided us with a declaration of

their compliance to our policies and

regulations on human rights protection.

We ensured that our contractual labour

is covered by the Contract Labour

(Regulation and Abolition) Act, along

with mechanisms to monitor the

compliance and report any violations.

We have a Supplier Code of Conduct

(SCC) that covers various human rights

aspects. We continued to sensitise our

employees and security personnel on

human rights and possible

associated issues.

The total number of incidents,

complaints or grievances of human

rights violations, along with the

backlog of earlier incidents is zero. No

complaints were received, nor are any

pending cases of child labour, forced/

involuntary labour, sexual harassment

and discriminatory employment.

Complaints received by

Ambuja Cement for violation

of human rights

ZERO