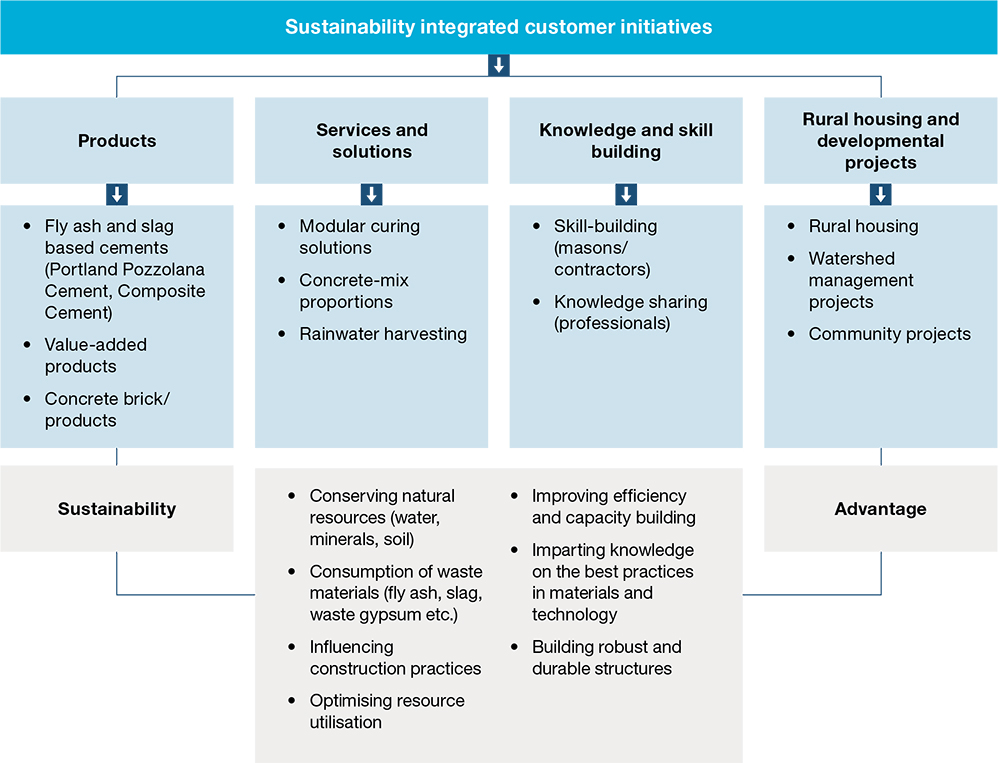

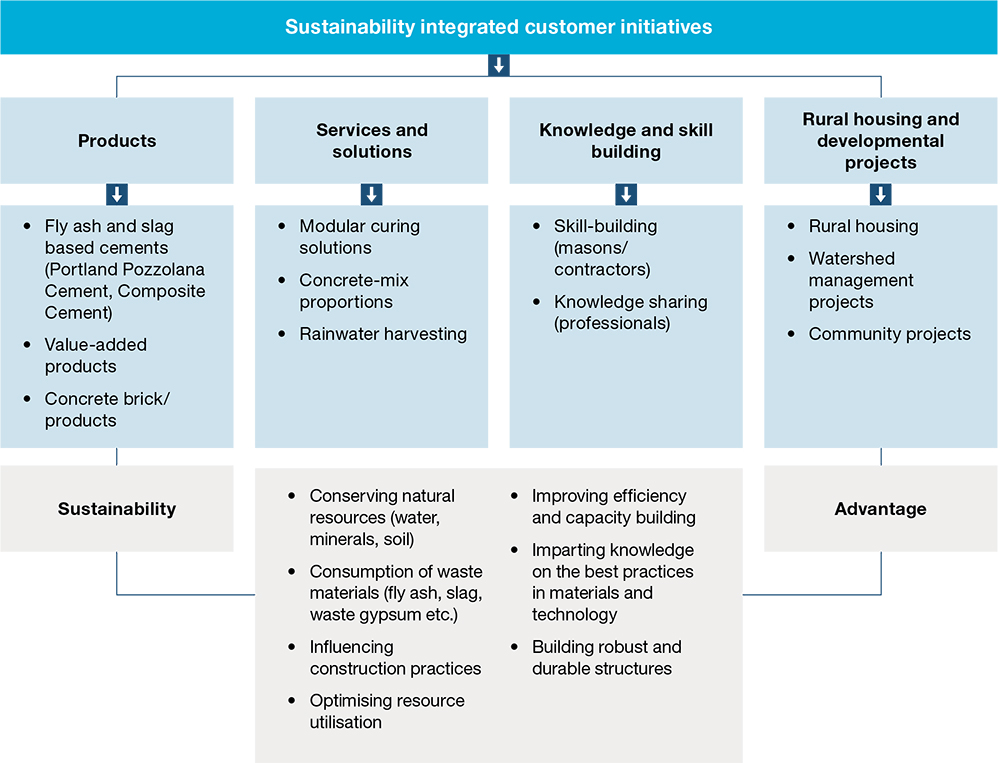

We fulfil the requirements of our clients while caring for the environment

We take proactive initiatives to help reduce our carbon footprint, while enhancing product quality and brand promise.

Our products and services help our customers and construction professionals reduce their carbon footprint, manage

maintenance requirements and cost of operations, making the projects greener and cleaner with lower environmental footprint.

Responsible and sustainable

products

For us, the key to achieve sustainable

construction lie in responsible

product design and development,

sustainable fuel mix, innovative product

development and resource efficiency

through efficient waste management.

As part of our extended product

responsibility, we have conducted a life

cycle assessment and have developed

the Environmental Product Declaration

(EPDs) of all the PPC and Compocem

products. This is also available on the international B2B portal ‘Environdec’.

We are India’s first cement company

to work out EPD after detailed life

cycle assessment.

Besides identifying and reducing

the environmental impact of our

product process/technology, these

also aid in addressing the health and

safety aspects related to the use of

construction products.

Our research and innovation team

works continuously on introducing

products which are not only innovative in nature but are also responsible and

sustainable. Continuing this trend, we

launched Kawach, a water-repellent

cement, during 2020. This product

has 33% less carbon footprint in

comparison to OPC products.

This premium quality solution has

been developed through our in-house

manufacturing and product innovation

efforts. Kawach is specially formulated

to prevent water seepage in the most

effective manner, resulting in improved

durability and lifespan of house.

During the year under review, our

Technical Services team provided the

following:

- Engineers provided technical

guidance and supervision for

slab casting to 14,478 customers

through video conferencing

during lockdown

- Concrete mix proportions at

14,721 sites

- Modular curing solutions at

2,391 sites

- Rainwater harvesting at 268 sites

- Preparing to apply for Eco Label for

our products (except OPC)

The three initiatives (Concrete Mix

proportions, Modular Curing, and

Rainwater Harvesting) helped us

in saving ~70 million litres of water,

a robust step towards sustainable

construction initiative.

During the year, we conducted various

skill-building workshops engaging

about 12,500 contractors, masons, and other construction professionals

(architects and engineers) through

class-room and virtual training

sessions, workshops and webinars

spanning over 39,000 man-hours for

skill-building.

Our PPC product from Darlaghat

plant (Himachal Pradesh) received

the ‘ProSustain’ certification from the

global certification body, DNV Business

Assurance, reflecting our promotion of

the adoption of responsible and

cost-effective measures for

incorporating sustainability into product

design, development, production, and

supply chain management.

New products

At Ambuja Cement, our continued

focus on IHBs and customer needs has

been the foundation for introducing

innovative products and solutions. We

work closely with our consumers in

understanding their needs. We have

identified that even newly-constructed

residential buildings face issues like seepage, dampness and leakages at a

very early age.

These are largely due to:

- Persistent warm or

high temperatures

- A tropical wet and dry climate

- Extreme weather conditions like

heavy rains and very hot summer

- Shallow water table

- Improper and ineffective drainage

systems causing waterlogging

We took this challenge and under

the umbrella of Ambuja Certified

Technology, launched new

water-repellent cement product –

Ambuja Kawach.

Since the launch, this product has

gained strong traction. Driven by its

premium positioning, it is driving

the overall net selling price of

Ambuja Cement.

Certification received

for PPC product from

Darlaghat plant

PROSUSTAIN

Sales of Kawach

cement in 2020

(lakh mt)

1.80

Less carbon footprint of

Kawach compared to OPCs

(%)

33

The digital transformation journey

is part of our strategic planning.

Digitalisation has been initiated in

the following areas—operational

excellence, controls and compliance,

and culture. The key focus of the

year was on implementing digital

tools in various parts of operations.

We strongly feel that digitalisation will

not just help in providing competitive

advantage but would also help in

creating a sustainable growth journey

in the coming years.

We turned this pandemic into

an opportunity and helped the

organisation emerge as digital savvy.

As a part of operational excellence,

we focused on three major areas—

enhancing asset optimising, improving

logistical efficiency and increasing

sales and marketing effectiveness.

Enhancing asset optimisation

In line with the LafargeHolcim’s

Plants of Tomorrow, we focused

on implementing digital tools that

helped in better asset optimisation

and ensuring higher plant availability.

We have implemented tools like

Distributed Control System (DCS), Tool

Location System (TLS) and Supervisory

Control and Data Acquisition (SCADA)

which are expected to enhance plant

efficiency and increase uptime.

We have introduced Internet of

Things (IoT) across the manufacturing value chain and are using artificial

intelligence and machine learning under

the project EDGE to facilitate rapid

deployment of predictive models and

seamless connectivity with plant

data sources.

We have picked up multiple initiatives

on predictive quality (cement fineness,

cement quality) and predictive

maintenance (VRM failure, refractory

life). This will help us in optimising

energy consumption per tonne of

cement and enable us to save cost.

We are conceptualising Digital Eye

to digitally monitor factory and plant

operations (through drone and video

analytics) to operate effectively and

enhance safety.

Increasing logistics efficiency

Logistics account for a substantial

part of the total operating cost in the

cement manufacturing value chain.

Hence, it requires effective fleet

management to rationalise cost. We are

leveraging various software packages

to enhance efficiency.

Enhancing sales force efficiency

We have implemented sales force

automation for our sales team.

This helps us in getting better

intelligence related to market dynamics

and better pricing of our products.

We have also rolled out a contractor

loyalty programme application where

more than 48,000 contractors are

enrolled with over 50% of them being active every month. This influencer

engagement initiative helps us in

strengthening the pull for our

premium products.

Invested to digitally strengthen

our sales and marketing team

(`lakhs)

33

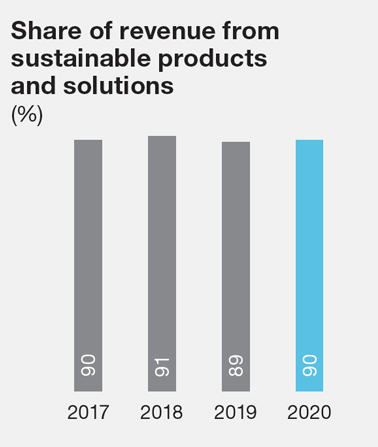

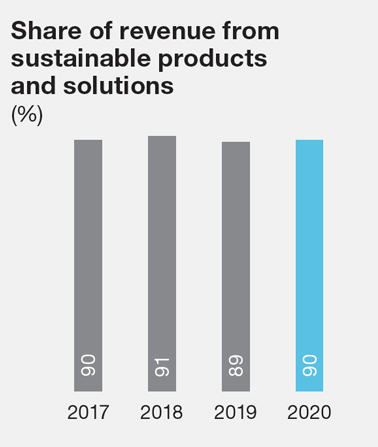

Share of revenues derived

from products used is

sustainable building design

and construction

(%)

~90