First, 18 contract workers were hand-picked for this job. Each health and safety protocol was extended to them as they entered the silo. Every move was manned by an expert emergency team trained to manage any crisis. A drone monitored movement and adequate levels of air supply maintained through a designated unit. Advanced equipment such as pneumatic whipping and cardox blasting were deployed under expert surveillance.

Precise planning, inspirational teamwork, deployment of advanced technology and swift decision by the senior leadership ensured a single-minded focus to complete the entire exercise in a record-breaking 11 days.

spirit could dwarf any challenges, thanks to a shared commitment by an amazing team.

spirit could dwarf any challenges, thanks to a shared commitment by an amazing team.

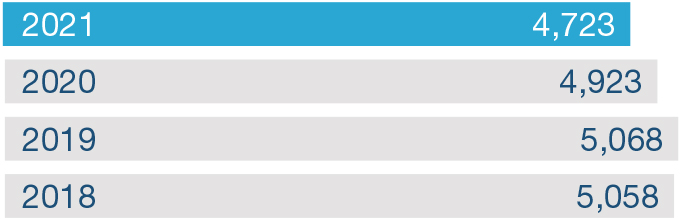

Employees

Developments and key initiatives |

KPIs |

|

EMPLOYEE HEALTH AND SAFETY |

Implement and monitor stringent health and safety measures across operations to ensure safety of people |

99 %employees vaccinated 101 . 8 Millionsafe on-site man hours In CY2021 |

DEVELOPING THE TALENT POOL |

Leveraging the digital ecosystem for employee learning and development, and leadership pipeline |

8hours on average of training imparted per employee |

EMPLOYEE ENGAGEMENT |

Focus on e-learning |

64e-learning courses |

Our Human Resources function is closely aligned with the overall business strategy and plays an important role in its execution. We recognise the importance of welltrained and motivated employees in achieving our goals.

We are aiming to become more inclusive and therefore the promotion of gender diversity has been one of the key features of our talent strategy. From setting a specific target to improve women’s participation in the workforce for the next three years to implementing programs and policies that improve worker diversity, we have clear objectives to improve worker engagement and build trust.

We have a ‘Zero Tolerance’ policy towards any kind of discrimination and harassment at the workplace based on the applicable laws and our internal directives.

Given the persisting uncertainties on account of the pandemic, we focused on promoting employee engagement in activities that their families could also participate in. Under the banner of ‘Umang’, a host of activities were organised, such as ‘I Can Talent Hunt’, that led to the discovery of capable dancers, singers and other talents among participating adults and children. There was also the ‘I Can Dream Project’, which, along with motivational and informative sessions like the ones of financial planning, boosted the morale of the workforce. Other such activities are planned for the future.

We have had a healthy flow of talent as a result of lateral movements and campus hires. During the year, we hired 342 new employees, 9% are women.

Healthy industrial relations have been our hallmark. We signed wage settlements across five units over the past one year. There was no loss of man-days or stoppage of work during the negotiations. While working within the framework of the Cement Manufacturers’ Association Wage Board agreement, we have been able to maintain adequate performance-based differentiation for our units. Disciplinary actions have also been conducted seamlessly as per laid down policies and procedures of the organisation.

In purview of the health crisis, we have launched a plethora of policies, support plans and mechanisms to ensure employee well-being and security. The Business Resilience Team launched its four-pronged action plan that included Crisis Management as well as Awareness & Communication. Our COVID-specific policies included leave, medical expenses for employees and family. Sparsh provided counselling and mental health support while outsourced agencies such as Health Spring, provided medical kits, vaccination support and tele counselling. Unfortunately, we also lost colleagues during the pandemic. An internal survey registered 90% employee satisfaction on the support provided by the Company during the pandemic.

As per Company policy, women employees are entitled to maternity leave for a continuous period of 26 weeks, or opt for two 13-week segments to cover the pre-natal and post-natal period as per convenience. During 2021, three women employees availed of maternity leave; two of them remained employed for the rest of the year after resuming work, and one is still on leave.

We are an equal opportunity employer providing equal remuneration for women and men. We aim to reach gender diversity of 10% in management workforce by 2025. The ratio of the average basic and total salary of women to men is 1.17:1 and 1.14:1, respectively management level roles and 1:1 for the entry level average total salary, considering all locations of our operations.

We have recognised trade unions affiliated to INTUC/AITUC/BMS, representing blue collar employees at different locations. Ambuja Cement respects freedom of association and allows its employees to join an independent trade union. Out of our total permanent workforce ~30% employees are covered by collective bargaining agreement.

At Ambuja Cement, Learning & Development is an integral part of our people strategy. Since the pandemic, the ACC ACL Leadership Academy (AALA) has leveraged the digital ecosystem to expedite the learning process through virtual instructor-led master classes. Short, customised web sessions have also been used for targeted groups which were coached on functional and leadership aspects. We also have dedicated learning programs for successor development, promoting the safety culture and for performance management among others. Numerous on-the-job training programs at the unit-level were designed and implemented with the help of internal faculty, subject matter experts and functional leaders.

ASPIRE

During the year, we launched Aspire, our successor development program for grooming talent for Plant Head positions through a blend of technical, business and leadership modules. The program includes both on-the-job functional tasks, assignments and mentoring by senior leaders in manufacturing. The training journey culminates in a cross-functional capstone project set by the Chief of Manufacturing. Each participant gets the opportunity to present his/her project to the Managing Director.

In addition to the Aspire program, the year saw us conduct a large sales training initiative with all Branch Heads on new dealer appointment. The training consisted of three modules and covered 261 Sales Managers. It was run through a ‘Train the Trainer’ mode, whereby nine Regional Sales Heads were trained to lead the modules.

A special program was designed in partnership with the Global Sales Excellence team to develop Regional Sales Office (RSO) Heads as Sales Coaches. The program not only imparted coaching skills through peer coaching sessions, but also the opportunity to practice these skills during the intervening sessions. The training covered 62 Regional Sales Heads and consisted of four modules.

AALA also created content for 128 micro learning modules on its Learning Experience platform and 64 e-learning courses in the areas of Sales & Marketing, H&S, Compliance and Success factors among others.

Diversity and Inclusion has been a long-term goal for the Company, and acts as a sustainability lever for business. AALA organised sensitisation programs for 65 senior leaders in Manufacturing and Sales, promoting conversations that reflected on bias at work, on building inclusive practices and action plans to promote gender diversity in the organisation.

SUPER ASSISTED INTELLIGENT LEARNING (SAIL)

Our L&D sessions utilised the online meeting platform, along with the in-house learning experience platform, Super Assisted Intelligent Learning (SAIL). SAIL is an application which works not only as a repository for programmes conducted, but also for content creation, curation and e-learning.

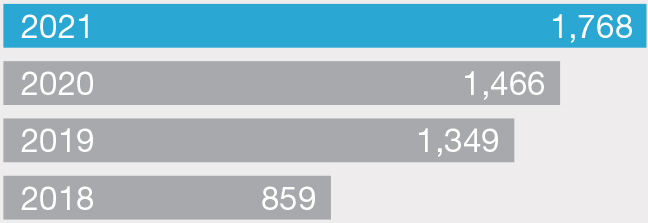

A total of 676 training programmes were conducted during 2021 including physical and virtual sessions on modules relevant for management and personal development

Throughout the pandemic, AALA has worked very closely with the Business Resilience Team and curated programs to establish meaningful connect with employees. It organised 12 webinars on COVID-19 and its management, mental well-being and resilience, covering a total of 4,511 employees, of which 1,882 were from Ambuja.

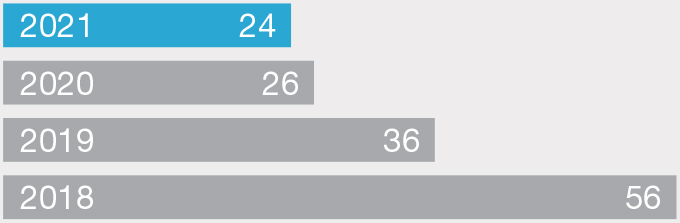

Share of women

employees

Targeted share of women

employees by 2025

We run some specific programmes to achieve consistent operations and standard maintenance within the plant along with operators, engineers and technicians for sustainable high performance.

In the midst of an ongoing pandemic, our commitment towards safeguarding the health of our people and ensuring safety at the workplace has been further stepped up. The Business Resilience Team has worked proactively to safeguard our people, putting in place a set of dynamic guidelines that evolved with the situation. As a result, more than 99% vaccination (both doses) has been achieved for our employees, dependants and workers. In a challenging environment, we continued to keep sustainability at the heart of our operations, and ensured this through necessary emphasis on better H&S performance.

The year saw substantial improvement of this performance, demonstrated by the fact that we had zero onsite and offsite fatalities in all our operating units. Till date, we have achieved 101.8 million safe manhours in our operating plants without any major accident. During the year, we also reduced our Lost Time Injury Frequency rate (LTIFR) by 24% and Total Injury Frequency Rate (TIFR) by 21% vis-à-vis 2020.

While we worked towards making our sites safer, we also took significant steps in to reduce manual handling across the country through the installation of automatic conveyor systems at seven of our largest warehouses.

Focus on frontline safety

Our strategy in 2021 was to sustain performance with a focus on frontline safety. The journey was planned under six pillars i.e. Onsite Safety, Zero Harm Culture, Systems & Processes, Control of Health Risks, Road Fatality Reduction and Environmental Excellence. The actual output was assured through a strong governance and assurance system that reviewed deliverables on a monthly basis.

Safety journey highlights

InCab assessments

done in 2021

iVMS installations

Reduction in offsite incidents with

67% lesser injuries through better

monitoring and training

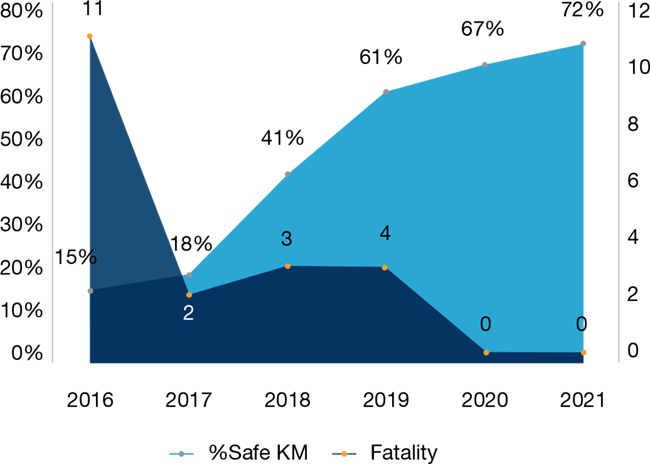

Safe journey

We have achieved two consecutive years zero road fatality. This was possible due to relentless efforts and passion of the teams involved for the past 5 years across all the sites of Ambuja Cement. We continued our focus around skill development and driving behaviour management based on critical inputs from TAC, backed up with consistent work around strengthening the process and lead measures. We moved from a meagre 14% Safe Km in 2016 to over 72% in 2021, achieved through driver behaviour management and learnt skills being applied while driving.

Outcomes

hours of safety trainings

in CY 2021

While we have delivered an excellent H&S performance in line with our values and long-term sustainability development goals, we are conscious of the need for continued commitment and efforts to better this performance. Our plan for this is in place and preparations are also in full swing to achieve the goals.