Challenging times in the recent past have proved the importance of building resilience into the core of any manufacturing industry. The path forward for our industry is clear - embrace digitisation and sustainability in the cement plant.

Ambuja has incorporated both these trends at the core of its planning as evident with its newest plant, Marwar Cement Works which is clearly a trendsetter as a Plant of Tomorrow.

With the vision that the cement plant of the future would boost productivity and efficiency, innovations were incorporated in Marwar right from the planning stage. A strong technological base facilitated a fully-integrated cement value chain, across different functions.

The entire operation of Marwar Cement Works is guided by the state-of-the-art Robotic Lab, which has the highest number of auto sampling points. Robotic arms across the plant, collect samples in capsules and transport to the lab for analysis with absolute accuracy guaranteed without any human intervention. Automated sampling has eliminated hazards associated with physical sampling besides creating a dust-free environment in labs and sample rooms.

Mining operations are assisted by another advanced technology that examines limestone samples at 1/10th of a second and updates operators on consistency of input materials within minutes. Besides time, fuel consumption is reduced due to consistency in raw material; and thus energy is saved.

This targeted and effective maintenance lengthens the lifeline of the equipment. The plant’s environmental footprint is minimised, securing its license to operate across locations. All non-value added tasks are automated and real-time information is remotely available at all levels to make better decisions.

spirit that has helped Marwar stay ahead of competition. we had only visualised a plant with this level of technology, automation and digitisation. For us at Ambuja, it is a dream come true.

spirit that has helped Marwar stay ahead of competition. we had only visualised a plant with this level of technology, automation and digitisation. For us at Ambuja, it is a dream come true.

Dealer

Employees

Construction professionals

Suppliers

Government and regulatory authorities

Developments and key initiatives |

KPIs |

|

CAPACITY EXPANSION |

|

6 . 1 %increase in grinding capacity in CY2021 |

ENHANCING EFFICIENCY |

|

30 bpsincrease in operating cost as a percentage of operating revenue in CY2021 |

SUSTAINABLE MANUFACTURING |

Reducing the environment impact of our operations through:

|

96 bpsincrease in thermal substitution rate 154 bpsimprovement in clinker factor in CY2021 |

QUALITY IMPROVEMENT |

Continuous investments in quality control and quality assurance measures |

> 95 %compliance in Annual Quality Programme |

Our manufactured capital consists the tangible objects that facilitate our day-to-day operations and delivery of our products. This includes physical infrastructure such as our land, buildings, production plants, mines on lease, heavy machinery, equipment fleet, and furniture and fittings among others.

At Ambuja Cement, we continuously invest to strengthen our market position and evolve as a more efficient, costcompetitive and environmentally sustainable organisation. Key initiatives of the year include:

To strengthen our logistical capability and enhance customer outreach, a new railway siding project at Rabriyawas has been commissioned at a total investment of ~`210 crore. Clinker and cement despatch by rail started from October 2021.

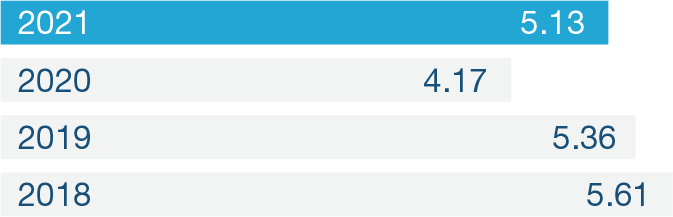

Spend on development and efficiency capex in 2021 (excluding Marwar expansion)

We adopt best practices in manufacturing. Our parent, Holcim, has developed a ’Cement Industrial Framework’, which defines the systemic approach towards manufacturing in its entirety, including people and processes. This framework is the guiding principle for all manufacturing activities at Ambuja Cement.

The framework has helped us in running operations more efficiently, strengthen plant availability and ramp up production seamlessly. Some of the highlights for the year includes:

In order to emerge as one of the most cost-competitive cement manufacturers in the country, we make continuous investments in the areas of clinker factor reduction, energy efficiency, raw material mix and fuel mix optimisation and enhanced use of alternative fuels and raw materials in manufacturing.

FOCUSED APPROACH FOR REDUCTION IN ENERGY AND POWER CONSUMPTION

Our optimisation efforts during the year resulted in the following:

PLANTS OF TOMORROW

Our investment in Industry 4.0 under the ‘Plants of Tomorrow’ programme is part of Holcim’s Strategy for Growth 2022. The initiative aims to make manufacturing more efficient through better plant optimisation, higher plant availability and a safer working environment. We are implementing several projects under the programme including FinCem and free lime prediction among others. Once implemented and certified, a plant usually promises 15-20% more operational efficiency compared to a conventional cement plant.

We have an impeccable record in delivering superior quality products. Our quality parameters are stringent and we keep a close tab on them to improve the overall Product Quality Index (PQI).

Our product quality monitoring strategy includes daily testing on defined quality parameters; three-day and 28-day measurement of coefficient of variations, clinker quality assessment; customer satisfaction; bi-monthly product benchmarking; bi-monthly application-oriented product testing; monthly testing of random market samples and monthly assessment of bag quality index.

We are compliant with all the statutory requirements as mandated by the Bureau of Indian Standards (BIS) as well as all weights and measures norms. As a statutory compliance, our bags display the contact details for customers to communicate any complaint, observation and query.

To ensure consistent results, we follow the round robin test methodology to identify issues and improve upon the same.

The past year saw continuation of the challenges created by the pandemic. Although disruptions were more localised during the second wave, they still caused uncertainty of demand and costs and put the supply chain under pressure.

Despite the challenges, our team ensured continuous supplies to all markets and healthy inventories with utmost focus on safety amidst while maintaining all COVID protocols. The major enablers were technology-driven operations and high agility among the teams as well as the service providers. With management focus on sales and operations planning, we were able to respond to market variability with agility.

Digitalisation initiatives across the supply chain helped optimise cost. Transport Analytics Center (TAC) is being used for finding deviations on the ground. We are also using best-in-class tools for network optimisation, Sales & Operations planning, e-platforms for freight procurement, etc. All our logistics excellence projects are driven through automated dashboards.

Several initiatives are being taken to improve efficiency and negotiate contracted rates. We are using the latest e-procurement platforms to discover real time freight rates. Vendor performances are being closely tracked and monitored to improve their value proposition.

The Driver Management Centres (DMC) that were closed during the initial phase of the pandemic were re-opened to engage with the driver community and counsel them towards safety-oriented behaviour. TAC has also helped develop more meaningful safety dashboards for use by the Driver Management Center (DMC). We are developing a Carbon Reduction tracker while working on bio-fuel trails, e-vehicles, lead reduction and mode mix to reduce our carbon footprint.

We have undertaken strategic initiatives in our value chain for energy sourcing and are developing in-house capacity to cater to our energy needs. Some of these include use of alternative fuels/Biomass, Waste Heat Recovery (WHR), renewable energy like, wind and solar and implementation of energy management system (ISO 50001:2011). A substantial part of our power consumption comes from our captive power plants at four integrated plants and one grinding unit.

Share of power sourced from captive units in 2021

Our integrated units have captive mines for limestone.

Our Group policy prohibits operations in the immediate vicinity of specific biodiversity zones, world heritage sites or International Union for Conservation of Nature (IUCN) category I-IV protected areas. We adhere to the Holcim Group Quarry Rehabilitation and Biodiversity Directive, requiring us to prepare a Biodiversity Action Plan (BAP) for sensitive sites. Every three years, a biodiversity indicator reporting system (BIRS) assessment is undertaken, as per IUCN guideline, and an improvement/action plan prepared.

All issues with the local community are resolved through dialogue and negotiations. There were no strikes or lockouts at our mines during the reporting period.

Bhatapara

Ambujanagar

Maratha

Rabriyawas

Darlaghat

Safety

Ecosystem protection

Constant monitoring

Efficient techniques