Climate Change has emerged as the biggest global challenge in recent times. With the planet warming at an unprecedented pace, the next decade will be critical in the fight against climate change. Avoiding the most devastating impacts of climate change by limiting global temperatures to 1.5˚ Celsius will require changing the way we power our manufacturing facilities and consume natural resources.

Ambuja Cements is a leader in climate action and sustainable practices in the sector. The Company is committed to climate change risk mitigation throughout its business operations and tailoring strategies to adhere to global best practices, aligning with the nation's economic growth aspirations and global climate obligations including, Nationally Determined Contribution (NDC) under the Paris Agreement and commitment to United Nations Sustainable Development Goals (UN SDGs). The Company’s climate strategy focuses on key pillars of reducing its carbon footprint, building resilience, strengthening its operations to the impacts of climate change, and developing strong frameworks to integrate climate change considerations into all decisions.

Ambuja Cement has framed an overarching corporate environment policy.

Ambuja Cements Limited is committed to Net Zero by 2050. The Near Term (2030) targets are validated by SBTi in line with a well-below 2°C trajectory. The Company has committed to reduce Scope 1 and Scope 2 greenhouse gas emissions by 21% per tonne of cementitious materials by 2030 from a 2020 base year. With this target, Ambuja Cements commits to reduce Scope 1 GHG emissions by 20% per tonne of cementitious material and Scope 2 GHG emissions by 43% per tonne of cementitious materials in this timeframe.

The Company is also committed to the GCCA Roadmap for Net Zero Concrete by 2050. These commitments warrant that the Company is making steadfast progress toward a net zero and sustainable future.

Ambuja Cement is taking decarbonization action across all operational site for decades and now we’re working towards eliminating fossil fuels and switching to renewable energy.

Cement is an energy-intensive sector. Efficient energy management is essential in controlling operational costs and reduce carbon footprint. Ambuja Cements continuously strives to reduce energy footprint across all its businesses. The businesses rely on a combination of energy sources (fossil fuels, alternate fuels, renewable energy, and waste heat recovery systems) for their operations.

In order to optimize energy consumption and achieve our Net Zero commitments, the current actions are focused around following verticals.

The Company has continuously invested in reducing thermal and electrical energy consumption per tonne of cement produced. Many of its plants fall under the Perform, Achieve and Trade (PAT) scheme, a regulatory instrument in India to reduce specific energy consumption. Under PAT, specific high energyintensive industries are identified as designated consumers within certain key sectors, who must file energy consumption returns every year and regularly conduct mandatory energy audits. The essential tasks in the mechanism are to set the specific energy consumption norms for each designated consumer in the baseline year and in the target years, devise a verification process for specific energy consumption, find ways of issuing the energy savings certificates, operationalisation of the trading process for energy savings certificates in addition to the compliance and reconciliation process for energy savings certificates. The outcomes are in the form of energy savings and subsequent carbon savings.

The Company’s specific thermal energy consumption has reduced from 760 kCal/kg of clinker produced in 2019 to 752 kCal/kg of clinker produced in FY 2023-24. The target is to reduce it to 710 kCal/kg of clinker produced by 2030.

Ambuja Cements, through its waste management arm Geoclean, takes a sustainable approach to managing industrial, agricultural, and municipal waste. Leveraging co-processing technology, Geoclean ensures the complete recycling and recovery of resources from waste. Ambuja Cements has invested significantly in upgrading its preprocessing and co-processing infrastructure, transforming highly diverse waste streams into a homogeneous mix suitable for co-processing in cement kilns. This process converts waste into an alternative resource, reducing reliance on traditional fossil fuels, conserving natural resources, and cutting greenhouse gas emissions. This also prevents such a huge quantum of waste being dumped into landfills, a co-benefit to protect precious, scarce land resource.

The Thermal Substitution Rate (TSR) or Co-processing rates are increasing over the years and Ambuja Cements has a target to increase TSR to 23% by 2030.

Renewable and Green Energy consumption significantly contributes to greenhouse gas (GHG) emissions in the cement business. Ambuja Cements is making sizeable investments in renewable and green energy to reduce its carbon footprint. This will lower its dependence on conventional electricity from grids and substantially shrink its carbon footprint. The green power share will increase to 60%, to be the largest in the industry with the planned expansion capacity. Ambuja Cements' renewable energy portfolio majorly includes solar and wind energy and WHRS in green energy.

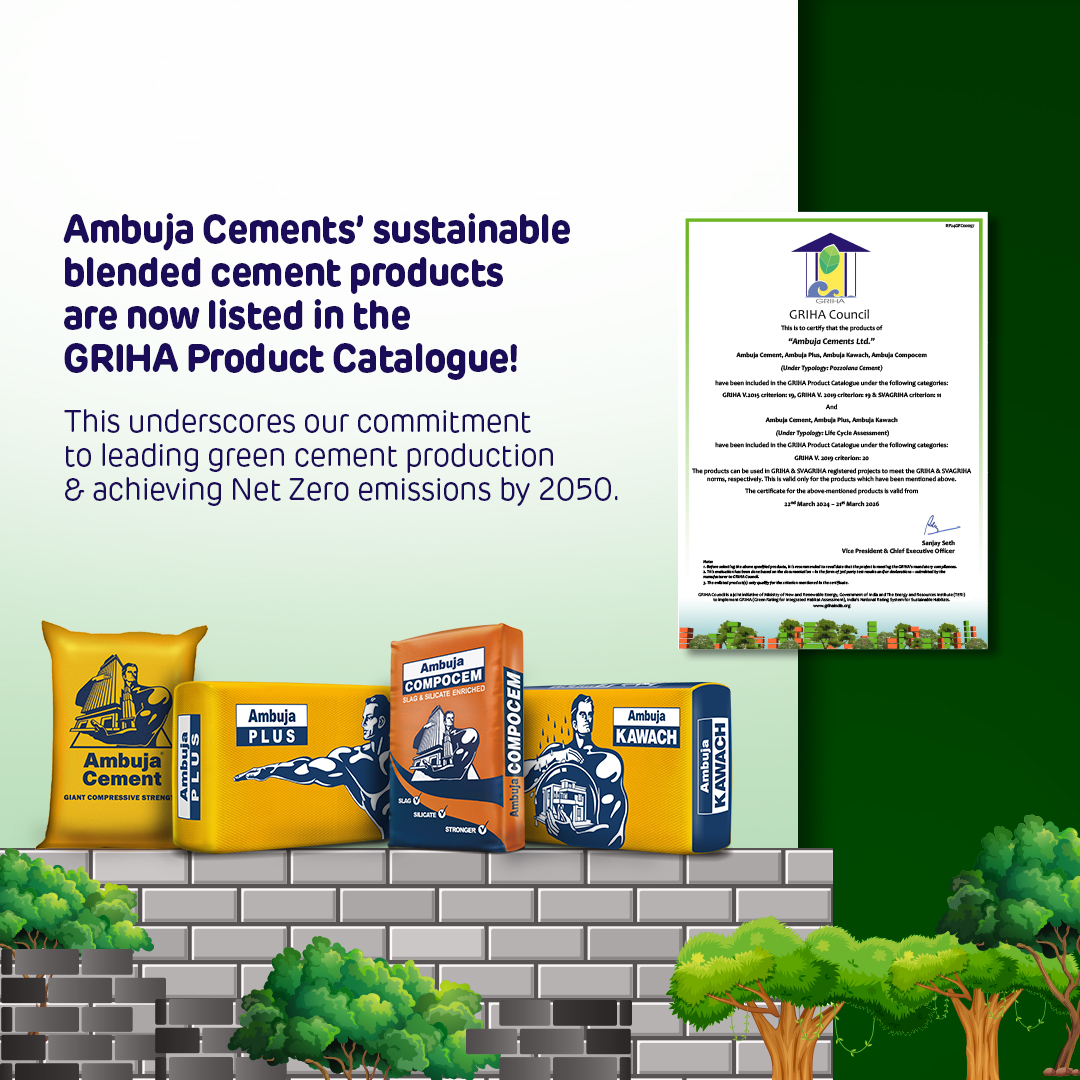

Ambuja Cements is the industry leader in manufacturing and selling blended cement, that is green cement with a much lower clinker factor. This not only helps the environment by using the slag and fly ash but also helps build durable and strong structures for the nation. More than 85% of the Company's production is in blended cements. The Green products of the Company are duly certified by GRIHA (Green Rating for Integrated Habitat Assessment), a national green rating system of India.