Waste Management

Addressing waste is a significant challenge that demands innovative solutions and collaborative efforts. We prioritize the judicious use of raw materials to minimize waste generation, ensuring that a substantial portion of our waste is recycled for productive purposes. The Company adheres to the principles of sustainable consumption of resources while reducing waste generation and complying with the tenets of circular economy.

Ambuja Cements prioritizes waste management by implementing industry best practices by using a large quantum of waste-derived resources, reducing its dependence on mined resources and, simultaneously, preventing their disposal into the environment.

The Company minimizes waste disposal through maximizing recycling and reusing efforts. The Company also ensures proper disposal of E-waste, hazardous waste, scrap, etc. through authorized recyclers registered with the regulatory agencies. At most plants, plastic waste and used oil is co-processed in cement kiln. There is no disposal of waste to landfills.

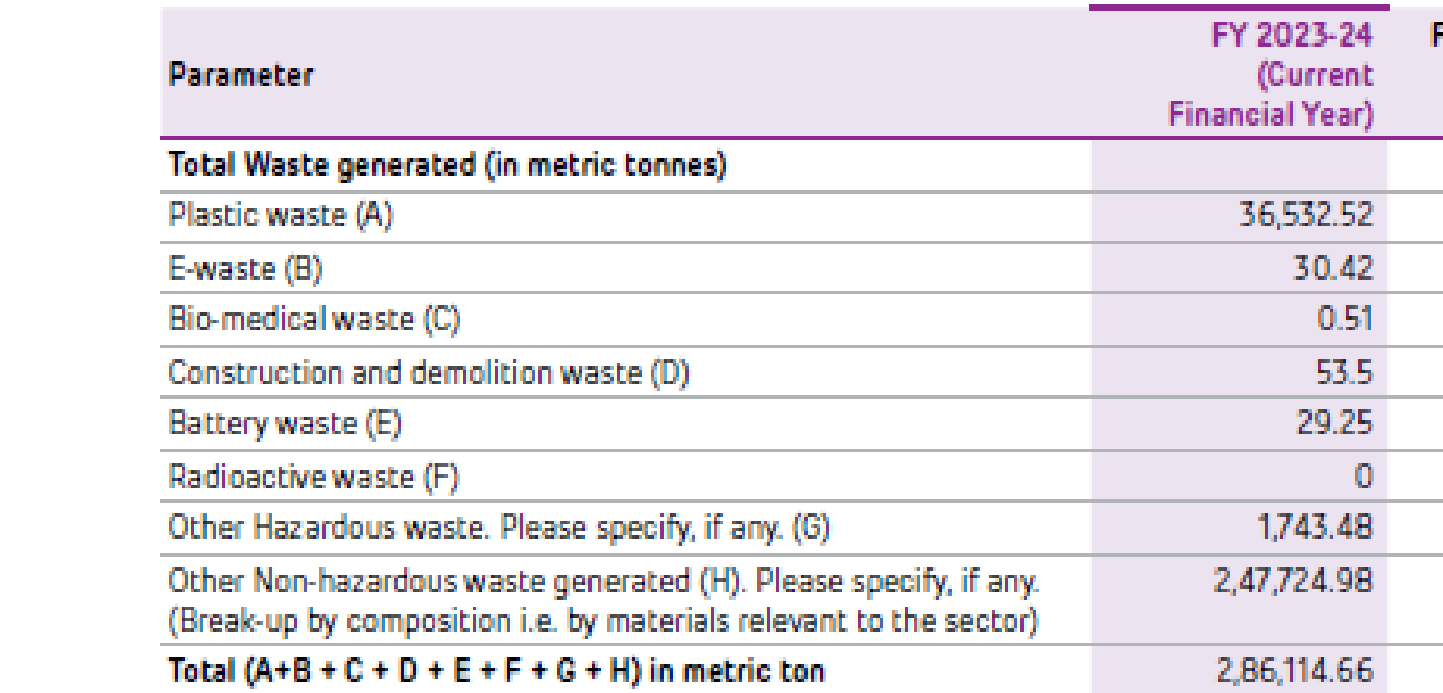

The Company generates following categories of wastes

- Plastic waste is mainly disposed of through co-processing by the Company and a very small quantity like burst bags through authorised scrap dealers

- Bio-medical waste is managed through Common Biomedical Waste Management Facilities duly authorized by regulatory authorities

- E-waste is managed through Common E-Waste Management Facilities duly authorized by regulatory authorities and most of the waste goes for recycling

- Hazardous waste (used oil, discarded drums) is reused at plants or is co-processed in cement kiln and the quantity which cannot be co-processed is sent to common authorized facilities

- Scrap is sold to authorised vendors

Some of the waste management initiatives include:

Zero Hazardous Waste Sent to landfill

- The Company successfully co-processed approximately 0.49 million tonnes of alternative fuels in the reporting period.

- The thermal substitution rates or co-processing rates are increasing over the years. substituting 7.76% of the total thermal energy in this FY.

- Ambuja Cements has a target to reach 23% by 2030.

Ambuja Cements takes sustainable approach to manage industrial, agricultural, and municipal waste. Leveraging co-processing technology, by ensuring complete recycling and recovery of resources from waste. Ambuja Cements has invested significantly in upgrading its preprocessing and co-processing infrastructure, transforming highly diverse waste streams into a homogeneous mix suitable for co-processing in cement kilns.

This initiative successfully diverts significant volumes of waste from landfills with tailored solutions.

In a resounding commitment to environmental sustainability, Ambuja Cements proudly embraces a 'Plastic Negative' ethos. The Company leads the charge with an impressive 8x plastic negative impact. It means that it removes 8x more plastic waste from the environment through co-processing than what is added by its plastic packaging bags. This remarkable achievement signifies its dedication to curbing plastic pollution and actively contributing to a cleaner future.

Ambuja is 8x Plastic Negative

The Company uses a large quantum of waste from other industries and reduces its dependence on mined resources and, simultaneously, prevents their disposal into the environment. This includes fly ash, slag, gypsum and other wastes. In FY 2023-24, the Company used 8.6 million tonnes of waste derived resources. Out of this, 0.49 million tonnes of waste was used for co-processing.

8.6 MMT Waste-derived resources in FY 2023-24