|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRODUCT QUALITY MANAGEMENT |

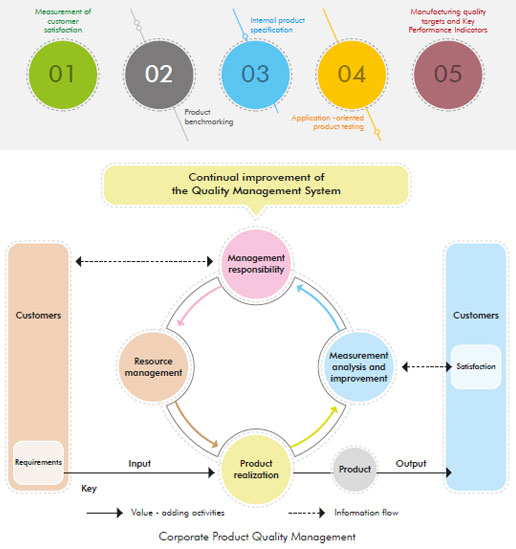

PR 1, EN 26 Assured quality' is one of the prime factors for sustainability of the industry. Product Quality Management (PQM) plays a significant role in this respect by ensuring cement quality, boosts consumers' confidence and leads to new products.Our PQM includes a comprehensive set of tools which are used to control and manage product quality across the Company. This system involves monitoring of 5 quality principles: 1. Measurement of customer satisfaction 2. Product benchmarking |

3. Internal product specification 4. Application –oriented product testing 5. Manufacturing quality targets and Key performance indicators. These parameters are integrated into a Product Quality Index (PQI), which is used for the manufacturing performance analysis and is tuned with ISO 9000. As shown in the Figure, the system starts with the customer requirements and ends with the final evaluation of customer satisfaction, including all the intermediate processes to ensure that the delivered product has the right quality. |

|

| ||

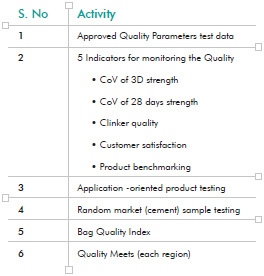

In addition, the company has also constituted Quality Committee, which refers to an institutionalized, regular meeting between Regional Marketing and Sales teams, Customer Support Service teams and Manufacturing teams (Plant Manager, Quality Control & Production). The objective of the "Quality Committee" is the continuous alignment between manufacturing, Customer Support and Marketing & Sales. This implies the review of the regional market situation, customer feedback and product benchmarking as well as manufacturing issues relevant to product quality. The on-going several PQM quality monitoring strategies are summarised on the right. LIMS (Laboratory Information and Management System) installed in 3 grinding units during the year 2013. In 2012 it was installed in all 5 integrated units and 1 grinding unit. LIMS is one integrated module of the "Technical Information System" which covers sample management, test results, compilation of data in desired format, statistical calculations and provides Certificate and Conformity of reports. PR 9 Corporate PQM carries out laboratory audit of all ACL cement testing laboratories annually. The non-compliances are recorded and checked whether they are taken care of in the following audit. During 2013 all ACL laboratories (Concrete & Mortar) were audited by a team of experts from corporate PQM. Mumbai and Chandigarh Concrete Testing Laboratories were ranked 'B' grade out of audited 7 ACL Concrete labs. This ranking also includes OH&S activities. Similarly, Quality audit of 17 mortar labs were carried out during the year.  |

|

|

Corporate PQM team has also conducted 3

workshops for Quality Control department to

up-grade their skills. 69 officials and laboratory

officials got benefitted.

Corporate PQM team has also conducted 3

workshops for Quality Control department to

up-grade their skills. 69 officials and laboratory

officials got benefitted.