|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TOWARDS SUSTAINABLE SUPPLY CHAIN |

Sustainability Principles in Procurement Ambuja Cements Limited (ACL) seeks to engage in long-term relationships with suppliers that commit to their social responsibility, that adhere to international standards such as SA8000 (Social Accountability) and ISO 14001 (Environment Management System) and that have systems in place to comply with relevant local provisions. The Company has set minimum requirements of Sustainability (including environment management, safety standards and social accountability) to be followed by any Supplier/ Third Party Service Providers (Contractors). A standard questionnaire on CSR & OH&S is sent to Suppliers while seeking requests for quotations in which appropriate clauses have been incorporated based on the nature of order. It is mandatory for new suppliers to provide these details. Most of ACL’s Vendors have been covered on all Plants basis. The aim of this is to help reduce the number of Supplier related incidents. In cases where Suppliers are not able to meet these minimum requirements, we engage in a dialogue and adopt mechanisms to improve our Suppliers’ standards. Re-assessment of qualified Suppliers’ compliance with these requirements shall take place within the regular schedule of Supplier re-qualification. However, in any cases of violation or obvious non-compliance by the Supplier, re-assessment must be immediate. Contractual Agreement of Compliance The Company also has clauses pertaining to Safety, Environment Management and Corporate Social Responsibility which are included in all the |

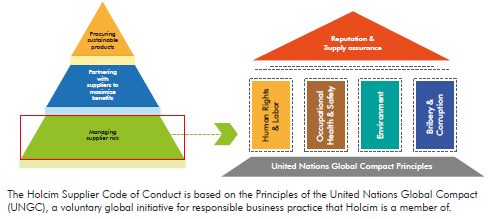

purchase Orders/Agreements. During the year, no cases of human rights violation (viz. incidences of child labor, forced or compulsory labor, overtime without pay etc.) were recorded in our operations. Sustainable Procurement Guidelines The principles of Sustainable Development - Value Creation, Sustainable Environment Performance and Corporate Social Responsibility - are integral to our business strategy. Our parent Company, Holcim has always been committed to procure responsibly and now the Group has constituted an integrated approach to ensure consistent management of the risk derived from doing business with Suppliers that do not uphold the Company’s standards on environment, OH&S and social responsibility. Holcim’s commitment to sustainable development is not confined to the boundaries of its operations and expects its Suppliers to do likewise. The Company has started the implementation of Sustainable Procurement through Holcim Supplier Code of Conduct. This has listed nine standards that Suppliers are expected to adhere to, in addition to complying with local and national laws and regulations. These standards cover Occupational Health and Safety (OH&S), Working Conditions, Freedom of Association and Non-retaliation, Forced Labor, Child Labor, Non-Discrimination, Environmental Regulatory Compliance, Management of Environmental Impacts, Bribery and Corruption. The objective of Holcim’s integrated approach is to manage the risks to corporate reputation and supply disruption. |

|

| ||

The integrated approach to implement sustainable procurement across the Holcim supplier base consists of 5 steps: Communication of the Supplier Code of Conduct Communication of Holcim’s expectations and terms of engagement to existing and potential suppliers. Supplier Prioritization Identification of potential high-risk suppliers based on Operating Companies’ judgment of local conditions. Risk Assessment Continuous evaluation of risk exposure through self-assessment, fact finding or verification, as determined by OpCos. Risk Mitigation Supplier development or replacement, as determined by Operating Companies. Scorecard Continuous performance-tracking of the management of SD related risks by our suppliers. Project LEAP! India The Project LEAP (Leverage-Engage-Align-Perform) was kicked off in 2013. The main focus of LEAP is the alignment of overall structure, processes, roles and responsibilities to support an improved leverage of Group spending. To achieve this, effective and efficient structures, processes, roles and responsibilities are needed, along with integration with external Suppliers as well as internally amongst procurement, technical and operations areas. This is the main aim of LEAP, which comprises of two modules:

|

In addition to the Supplier Code of Conduct, Ambuja has a Green Procurement Policy which we follow in our Procurement while Purchasing Goods/Services.

In the Organization work stream, we launched multiple initiatives to address the key issues that were identified during the diagnostic phase. All these initiatives have been rolled out, which has led to significant improvement in employee morale, greater interactions with stakeholders and clarity in roles and responsibilities. To ensure that the efforts are sustainable, we have defined clear quantitative metrics to measure our performance, which will be continuously tracked and shared. In Savings Delivery, we have completed deep dives in 6 categories - gypsum, bags, coal (as part of Project EARN!), services, maintenance material, and fly ash. Multiple initiatives with timelines and savings target have been mobilized. Globally, we are using a new web based Procurement Initiative Tracking Tool (PITT) to track these initiatives. |

|