|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RESPONSIBLE MINING |

Sustainable mining practices are the ‘dictum’ for Ambuja Cements Ltd. The Company has mining footprints in various regions of the country which covers Rajasthan, Gujarat, Maharashtra, Chhattisgarh and Himachal Pradesh region. MM 11 To obtain limestone as chief mineral from its captive mines, mainly two types of methodologies are deployed while complying with all the Govt. legislations. The soft, crumbled / friable limestone is scratched by efficient mining techniques using Surface Miners which is exclusively utilized in Gujarat region, whereas the harder and compact ‘limestone’ is extracted through advanced hi-tech controlled drilling blasting techniques with in-built arrangement of providing dust free operation. To minimize blasting effect / noise pollution, vibration and fly rock generation ‘Digital Energy Control System’ has been introduced. It reflects our concern and commitment towards surroundings and environment protection. As of now ACL is operating 10 mines which are located at various integrated plants in India. In Gujarat, 5 of our mines are being operated by surface miners while other mines located in northern, central and western parts of India are mined by drilling and controlled blasting to extract limestone. Statutory Mine Plan, Scheme of Mining, Mine Closure Plan, Quarry Updation Work is carried out in-house by qualified, competent personnel with the help of the latest technology and software. Other technical studies viz. Hydrological, Geotechnical, Remote Sensing and Land use/ Land cover studies are being conducted through reputed consultants. Various types of technical events including Mines Environment & Mineral Conservation Week, Mines Safety Day, World Environment Day etc. are being celebrated in ACL mines which spread awareness and promote the welfare program among the surrounding community and foster the technical advancement in day to day operations. Concurrent planning on water harvesting, plantation and other environmental protection activities are also taken care. Besides adoption of modern technologies in drilling & blasting process, we also exercise raw material optimization through the latest computer applications (Quarry Scheduling Optimization), optimizing screen reject, slope stability by coconut |

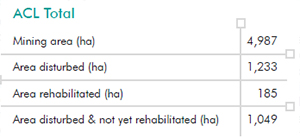

fiber blankets, logistics optimization and proper rehabilitation etc. EN 11 & EN 12 All ACL’s operating sites have been assessed for environment impacts and necessary systems are put in place to prevent the occurrence of adverse impacts. The Company continuously strives to operate in an environmentally responsible manner. Protected area exists within 10 Km of our mining or plant operations at two locations, Darlaghat and Ambujanagar. The Company has initiated Wildlife Conservation Plan and Biodiversity Action Plan for management of biodiversity. MM 1 Amount of land (owned or leased, and managed for production activities or extractive use) disturbed or rehabilitated.  MM 2 None of the sites are operating in immediate vicinity of specific Biodiversity zones. Biodiversity (Flora and Fauna) studies have been conducted by third parties for almost all mining areas. Additionally, we are implementing Holcim Biodiversity Directive with a mandate to prepare Biodiversity Action Plan for our sites. MM 3 Total 42,61,369 tonnes of overburden/interburden or waste material was generated during the reporting period. Further, there is no generation of tailings and sludge. The disposal of waste material is being done through excavator-dumperdozer combination. Dumping is carried out in non mineralised area. There are no associated risks identified so far. The dumps are well designed and maintained with predefined slope angle for maximum stability. |