|

As an organisation, Ambuja is conscious about creating a

positive impact on our environment and society. It is our

constant endeavour to find ways to bring about change

that will positively impact the environment without

compromising our operational standards. Safe waste

management is one of the biggest environmental challenges

faced by the country today. Ambuja is aiming to provide

state-of-the-art waste management services to the industry

and society through waste co-processing in cement kilns

under our Geocycle brand. We aim to utilise wastes from

different industrial, agricultural, and municipal sources as

alternative fuels and raw materials (AFR) that can help in

conserving scarce conventional fuels used in our kilns and

captive power plants (CPPs), to achieve our goal for

sustainable development and mitigation of climate change.

The quality of the end product, operational control and

occupational health & safety of the employees remain the

chief concern during co-processing. Co-processing helps

in substitution of fuels, recycling and elimination of waste,

and also facilitates the scientific destruction of wastes that

cannot be recycled and/or reused. In some cases, trial runs

becomes necessary for regulatory approval. Business advantage accrues in the form of energy costs, energy

security, and reduced consumption of scarce resources. |

Ambuja has been working with Geocycle to expand waste

streams and ensure that they are available & used efficiently

through better sourcing and marketing. Other measures by

the Company include advocacy for enabling a policy

framework to promote the use of AFR; plant AFR potential

profiling; installation of infrastructure & machinery for

handling and storage of AFR; and testing facilities for AFR.

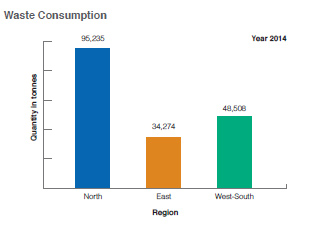

Waste consumption increased substantially in 2014.

The range of waste streams also increased significantly

and catered to new customers.

With higher utilisation of

alternative fuels and raw materials, Geocycle has also made

significant contribution towards replacing traditional fuels.

The year 2014 also marked the year of the final set up of

our pre- processing platforms in four locations.

New and more

automated installations will enable Geocycle to accept varied

waste streams from across India & make them compatible

for co-processing in kilns. Geocycle has also focused on

strengthening the ACert implementation for comprehensive

assessment of all operations related to co-processing. |