Today, environmental & development issues are at

loggerheads in many parts of the world. We at Ambuja

Cement have adopted sustainability as our way of

doing business with due regard to the environment,

energy management, efficiency enhancement, safety

and community concerns. We invest in environment

protection measures with a view to leave no or low traces

of our operations. We have installed continuous emission

monitoring systems (CEMS) at all our nine kilns and

continuous ambient air quality monitoring systems

(CAAQMS) at all our plants for real-time monitoring of

all vital pollution parameters. The Company places

considerable stress on emission monitoring and

management.

The Company is assessing and initiating steps to meet the

newer and tighter environmental standards in India. ‘New

Emission Standards for Cement Industry’ was released by

the Government in August, 2014. This requires significantly

newer technologies and investments which are currently

under evaluation. We believe that our vision of sustainable

development and environment conservation can be

achieved more effectively through a structured and

systematic approach. Ambuja is empowered by its

overarching 'Corporate Environment Policy' along with

unit-specific policies. The corporate policy is in conformity

with the Ministry of Environment and Forests‘ guidelines.

In addition, we also have various specific policies like the

Corporate Sustainability Policy, Climate Change Mitigation

Policy, and Green Procurement Policy which mention the

Company’s approach towards sustainable development,

climate change mitigation, and greening of the supply

chain. All our manufacturing locations have an environment

team equipped with laboratory facilities to enable complete

monitoring of stack emissions, ambient air quality, noise

level, and water quality. These teams are also responsible increase AFR use; and reduce the use of limestone by

reducing the clinker factor with increased use of fly ash.

Cost of major raw materials, fly ash and gypsum,

increased by two per cent on a ‘per tonne’ basis. During |

for implementing various environment initiatives at the

units. A key element of our strategy towards environmental

management is the environmental assessment system.

We have implemented Holcim’s Plant Environmental Profile

(PEP) system for the annual monitoring of plant’s

environment performance. In addition, corporate

requirements including CO2 Emissions Reporting Protocol,

AFR Directive, Asbestos Directive, PCB Directive, Quarry

Rehabilitation Directive, Water Directive, Biodiversity

Directive, and Environment Monitoring and Reporting

(EMR) protocol, were also followed.

PEP System

The Plant Environment Profile (PEP) is the Company's

internal annual environment performance assessment

system. The assessment is based on a detailed &

standardised online questionnaire, which incorporates

key elements of ISO 14001 along with key performance

indicators covering a wide range of topics. These include

atmospheric emissions, energy and material consumption,

water, and waste and quarry management. At the end of

the assessment the environment performance index score

is calculated. The score is used to rate plants internally

and to benchmark them against the Group’s other

operating plants.

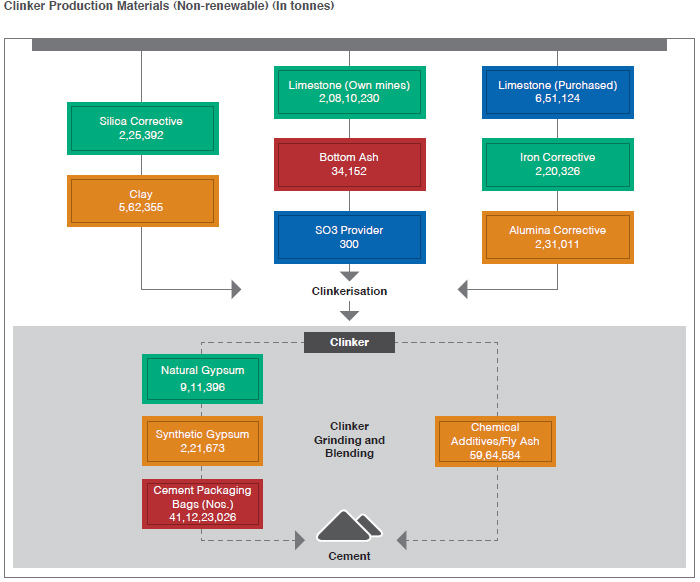

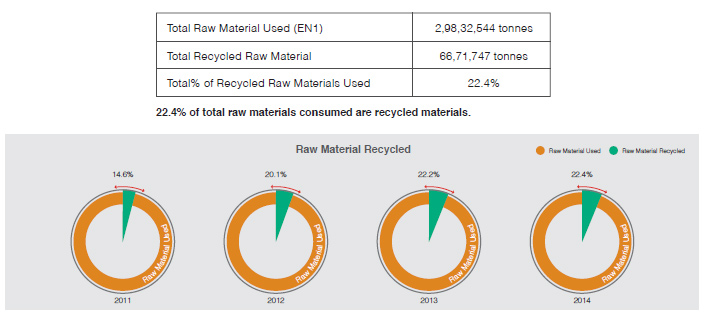

Management of Natural Resources

Cement production involves use of natural resources as

key raw materials. As a responsible Company, Ambuja

recognises the global pressures on natural resources.

Efforts are in place for better material management, like the

use of low grade limestone, synthetic gypsum waste from

other industries, as well as fuel. As part of our sustainability

initiative, we aim to increase biomass use to 10% by 2017; the year, the royalty on limestone was hiked by 27%.

Overall, the raw material cost per tonne increased by

approximately 13% over the previous year. |