|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Sustainable Supply Chain |

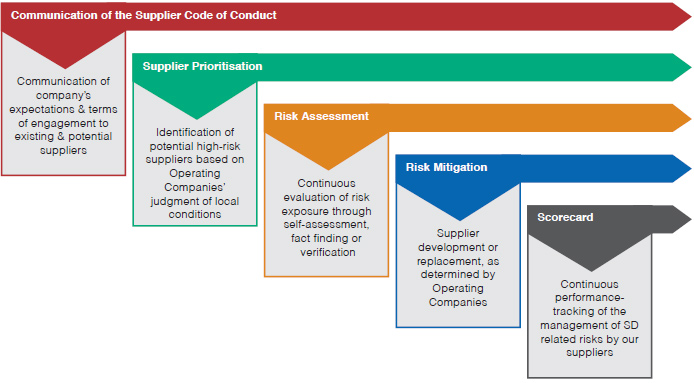

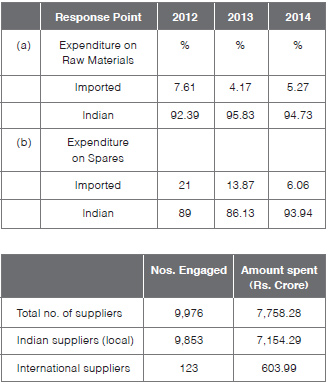

| We have a vendor base of over 10,000 suppliers including reputed manufacturers and trusted brand names, spread across the country. Our vendors are technically and financially sound and have the intrinsic capacity to supply material of the desired quality on time. They are usually ranked among the top four vendors in their particular industry segment. We prefer vendors who demonstrate competition in markets. We attempt to build synergy and long term relationships with our suppliers. To ensure that they understand and comply with our requirements, we provide them with training on ethics, anti-corruption and anti-bribery. These sessions, each of which covers close to 50 suppliers, are conducted for high risk, high spend suppliers across all our areas of operation at regional levels. In the last year we conducted six such training sessions. Regular interaction with the vendors takes place through phone, virtual conferences, e-mail or in person. The key concerns identified are related to quality, quantity and sometimes payments. Our supplier relationship helpdesk takes up such concerns with the relevant plants as soon as possible. During 2014, Holcim engaged a global consultant, PICS, to assist in educating existing and new vendors in various aspects pertaining to OH&S, HR, legal, environmental & ethical issues as defined in the Supplier Code of Conduct. It is proposed to continue the same in 2015 and cover those four to five per cent of vendors who fall in the high |

good corporate citizenship and promote sustainable

development. The vendors supply material as per our

specifications. They are treated as business associates,

with respect and dignity. Adequate care is taken to ensure

transparency in the procurement processes. Our

procurement policy has a clearly defined code of practice

for procurement conduct and encourages fair and open risk, high spend category and account for 50% by value of

procurement (excluding Government spend).

A high standard of professional conduct is expected from all our suppliers. We also continued our efforts to assess critical suppliers based on their sustainability practices. It has been a challenge to engage with our suppliers, as they do not yet fully appreciate the importance that sustainability can play in improving their businesses. But once they have been evaluated, this information will help us map our suppliers’ practices and will be used to establish corrective action wherever required. Suppliers will receive feedback on their practices, which will allow them to work with Ambuja (and Holcim) on improving their performance. Thereafter they will also be able to grow their businesses. Optimised sourcing through Central Procurement Organisation (CPO), cost optimisation, engineering and the supply chain are also important levers to improve performance. |

|

| The supply chain process of a manufacturing company constitutes a major part of its operating cost. Apart from being a prominent cost centre, our supply chain operations involve many key internal and external stakeholders who are affected by Ambuja. Procurement and supply operations involve a large group of multi-disciplined personnel. It is thus important to ensure efficiency and transparency in our oerations. Our corporate and plant compliance equirements. About 600 existing suppliers have been screened through his process. In cases where suppliers are not able to meet these minimum requirements, we engage in a dialogue with them and adopt mechanisms to help them improve their standards. In cases of persistent non-compliance or obvious violation, we decide to terminate these relationships. Contractual Agreement of Compliance All our purchase orders or agreements that we enter into incorporate different clauses related to safety, environment management, and corporate social responsibility. We have started the implementation of sustainable procurement through the Supplier Code of Conduct which is meant to provide a clear summary of the Company’s expectations from its suppliers in all procurement dealings. Transparency and accountability should be strictly adhered to in all procurement activities. There are nine listed standards that suppliers are expected to adhere to, in addition to complying with local and national laws and regulations, which are:

Contractual Agreement of Compliance: All agreements with suppliers, such as purchase orders, purchase agreements, service agreements and frame agreements have to refer to the supplier’s compliance with SA8000, environmental management and legal compliance requirements. With its signature or order confirmation, the supplier accepts and agrees to adhere to these requirements. In the reporting period, around four to five per cent of our new suppliers were screened using environmental criteria. |

procurement department ensure that they assess and contract suppliers whose practices comply with SA8000 and ISO 14000 standards. We have clauses pertaining to corporate social responsibility (CSR) and occupational health and safety (OH&S) which are included in the purchase orders/ agreements. We encourage our suppliers to take up ‘self-assessment’ based on a checklist integrating SA8000, environmental management and legal All Suppliers operating from within Indian territory (national suppliers) are treated as local suppliers. Also, wherever viable, Ambuja considers vendors located in the proximity of its plants.  Our operations are well connected with the manufacturing units and sales units spread across the country. We have local procurement teams to take care of day-to-day purchase requirements. Central Procurement Organisation (CPO) engages in high value purchase of various commodities such as coal, raw materials (gypsum, iron ore and bauxite etc.), capex items, steel and various other essential services. Most of these requirements are directed to CPO and purchases are carried out centrally.  |

|

|